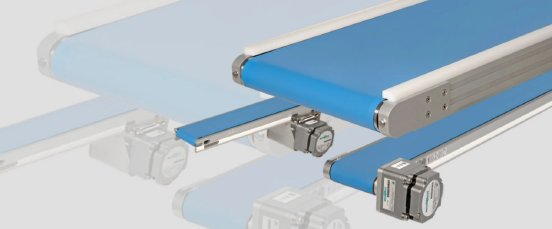

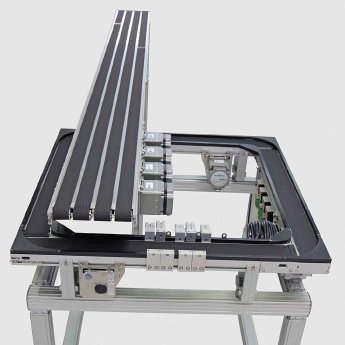

Preventing downtimes in production

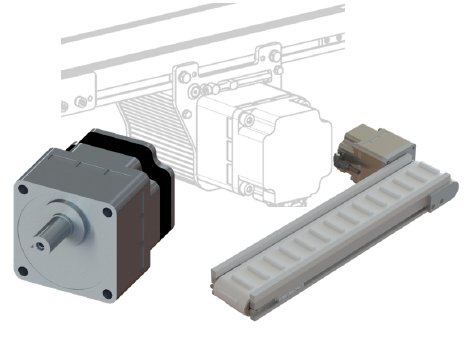

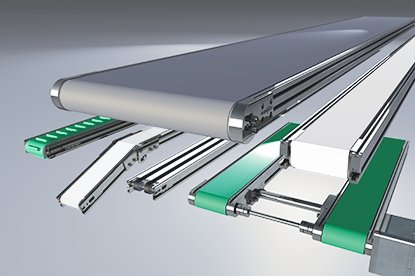

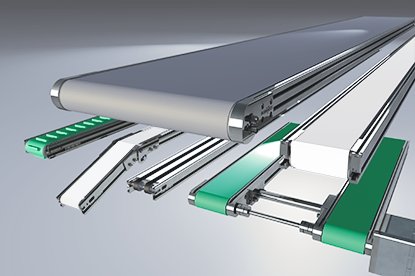

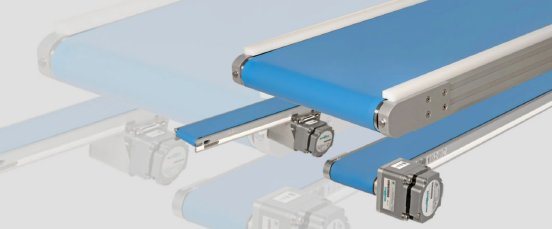

Unexpected production downtime - an unexpected scenario that can happen at any time. This is especially true if the wear is not immediately apparent, such as in the case of conveyor belt drives. As downtimes can have a considerable impact on production processes, it is advisable to keep a replacement motor in stock. In this way, you can react promptly in an emergency and reduce interruptions to a minimum.