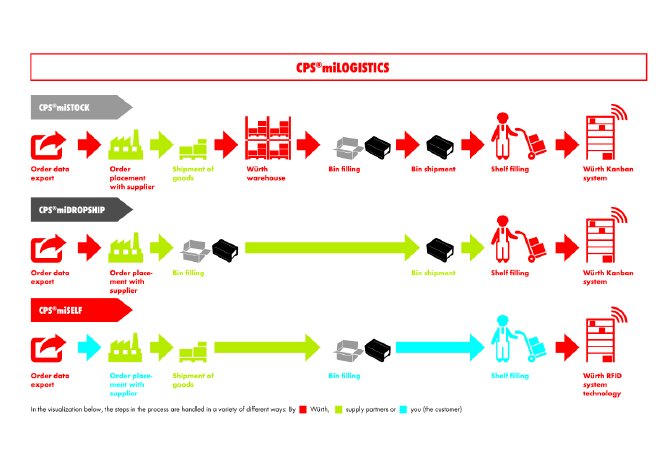

C-Parts must always be available at the right time, in the right place, in the right quantity and quality in a flawless production process. To ensure this supply for industrial customers, Würth Industrie Service relies on a Kanban system for its portfolio of more than one million items including screws and bolts, fastening and connecting materials, tools, technical chemicals and PPE. In collaboration with more than 50 cooperating suppliers, Würth Industrie Service offers customers a comprehensive solution in terms of quality and scope of standard and special parts. By contrast, non-Würth parts have thus far been managed separately by customers. With CPS®miLOGISTICS, a solution has now been developed which also integrates such items and the associated suppliers into the fully integrated procurement system. Using this solution enables customers to instantly and easily expand their C-Parts management with additional suppliers and product groups. With the aim of reducing the number of suppliers, freeing up resources and saving storage capacity, depending on their individual needs, users choose one of three options – CPS®miSTOCK, CPS®miDROPSHIP or CPS®miSELF – for their supply chain. At the same time, customers benefit from state-of-the-art technology for their C-Parts management and a digitised value chain for all suppliers. This simplifies the flow of information between the different departments within the company, creates transparency about manufacturers and suppliers and thus ensures greater productivity.

Complete management and stocking via CPS®miSTOCK

Würth Industrie Service uses the CPS®miSTOCK solution to store the goods of the customers' individual supplier in its own logistics centre. Delivery then takes place just in time via the Kanban system from Würth Industrie Service. In this way, Würth Industrie Service ensures maximum security of supply even for items that have long delivery times and which consequently had to be kept in stock up until now by the customers themselves. This reduces the customer's stock and the capital tie-up – and not least saves space in their own warehouse.

CPS®miDROPSHIP: Integrate external suppliers into Kanban

As part of CPS®miDROPSHIP, Würth Industrie Service integrates further suppliers defined by the customer into its own Kanban system via a third-party order processing system, which Würth Industrie Service qualifies accordingly for the processes in advance. The partner suppliers fill and label the Kanban bins on behalf of Würth Industrie Service in their own warehouse and send them directly to the customer. Würth Industrie Service in turn then takes over the shelf filling service on site. Customers benefit from automated materials planning and inventory management, and at the same time can integrate their individual desired items into the Würth Kanban system.

Independent management via CPS®miSELF

The basis for CPS®miSELF is the RFID Kanban system from Würth Industrie Service, in which any item or supplier can be incorporated independently. Not only are C-Parts possible, but also A and B-Parts, for which other purchasing processes usually apply; integration into the user's intralogistics is also possible. Customers use RFID technology to respond to fluctuations in demand at an early stage and can precisely control the flow of goods. The effort involved in configuring this technology in existing processes is minimal, but it directly increases productivity. Because production employees no longer have to order themselves; rather, the system independently knows the exact need for material and reports it fully automated to the supplier. This also prevents manual errors during reordering. With CPS®miSELF, the user uses the system and the associated hardware such as bins, labels and shelves. The Kanban system digitally reports the requirements for all items and provides the corresponding data. Subsequently, the customer himself triggers the order of the required products from the supplier of his choice. Depending on the requirements, Würth Industrie Service offers the provision of pure bin information, master data management and even interface connection with additional automated materials planning.

Logistics 4.0

The CPS®miLOGISTICS concept enables industrial customers, for example, to combine various suppliers in a standardised C-Parts management solution, and at the same time to use Würth Industrie Service's service also for items outside the Würth product range. The partner for C-Parts management thus offers a solution that enables users to digitise their entire supply chain and make it more transparent. The processes are designed to be so simple and streamlined that customers and production staff no longer have to order themselves. On the contrary, the intelligent system independently knows the exact need for material and reports it fully automated to the service provider for C-Parts management. Thus, in future, the entire supply chain will largely control itself.