Understanding the Print & Cut process for laser cutting UV-printed materials

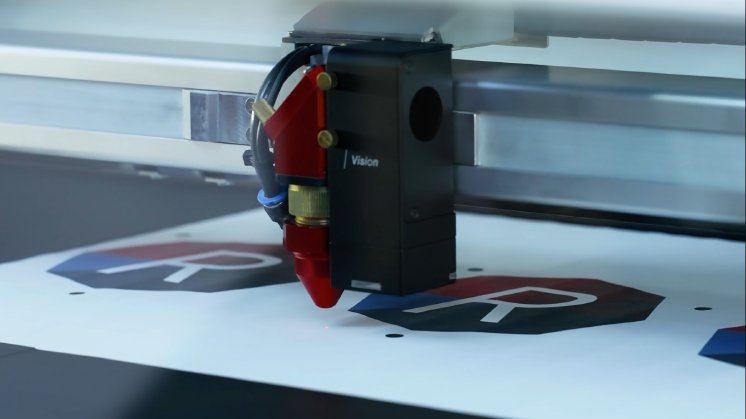

Print & Cut involves first printing a design onto rigid materials like acrylic or wood, followed by laser cutting the printed item based on exact contours. Using registration marks placed alongside the printed design, Trotec's Vision Print & Cut camera system detects alignment points before the cutting process begins. This ensures that the laser cuts are perfectly matched to the printed layout – even for highly detailed or complex shapes.

This approach minimizes manual effort and reduces material waste, offering a clean, efficient solution for producing consistent, professional-quality results.

What to consider when laser cutting printed acrylic or wood

- Printed Acrylic

- Printed Wood

All suitable acrylic and wood materials are available through the Trotec online shop. With predefined material parameters integrated into the Ruby® laser software, users can skip time-consuming test runs and achieve optimal results instantly. This seamless integration makes Trotec’s materials and laser machines the ideal pairing for efficient Print & Cut workflows.

Trotec Speedy Series: Ideal laser machines for printed acrylic and wood

Trotec’s Speedy Series laser systems offer a reliable, cost-effective solution for Print & Cut workflow, enabling users to cut even the most detailed geometries with high speed and minimal waste. Whether producing signage, models, prototypes, or retail graphics, the Speedy Series delivers efficiency and professional results across a wide range of materials.

In addition, Trotec provides comprehensive technical guidelines on file preparation, camera calibration and material settings for Print & Cut applications on their website, helping users achieve the best possible results.