In the field of modern resin processing, TARTLER’s compact dosing and mixing stations of the MDM series offer a wide range of applications. Whether it’s the production of lightweight composite components from fiber-reinforced plastics, encapsulating electronic assemblies, bonding housing shells, coating surfaces, or manufacturing foam – the MDM model range offers a suitable system solution for these and many other tasks. All systems in the series are designed for processing small and medium-sized quantities of synthetic resin and, depending on the variant and equipment, allow the user to achieve qualitative standards as they are known from industrial production. “At the same time, they are the perfect entry point for resin processors who want to gradually transition from manual mixing to automated mixing technology,” says company CEO Udo Tartler.

Cost-Effective System Transition

What the managing owner of the TARTLER GROUP is referring to is best illustrated by the top model MDM plus. It bridges the technological gap to the company’s large Nodopur systems, which are used worldwide, offering small-scale processors a means for high-quality metering, mixing, and application of modern resins. Specifically, this means that manufacturers of containers or pipes made of GRP/CFRP using filament winding (fiber winding technology), or of sophisticated lightweight construction elements for aviation using injection molding (resin transfer molding/RTM) or, also, manufacturers of profiles using extrusion (pultrusion) can use the MDM plus from TARTLER to make a cost-effective system change from manual or semi-automatic synthetic resin processing to fully automated, controlled dosing, mixing and application technology. The compact system can also be used for vacuum infusion technology. According to Udo Tartler, “the MDM plus can be adapted to almost all processes and applications of resin processing with the help of numerous modular extensions.” It is particularly noteworthy at this point that the system can also be equipped with intelligent flow rate control, allowing continuous, precise, and automatic control of mixing ratio and output.

Technological Bridge

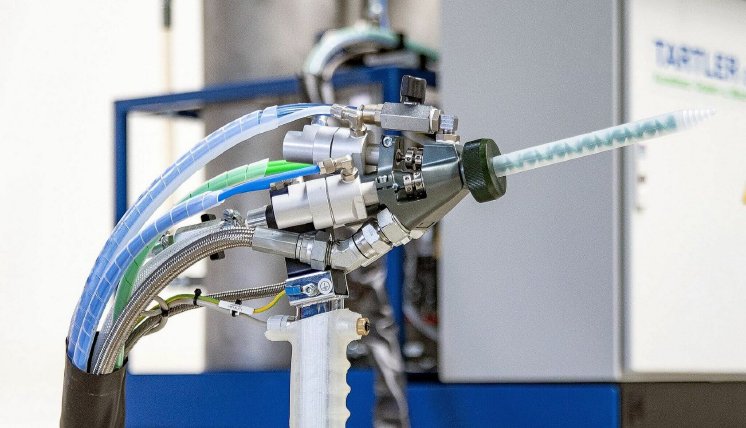

In terms of equipment and performance, TARTLER’s MDM plus bridges the gap to the company’s large Nodopur systems. It sets itself apart from the smaller models in the MDM series primarily through its higher output (up to 6.5 kg/min) and separate drives for each material component (resin, hardener). Its typical features also include a 7-inch touch panel, a mobile basic structure with drip tray and the aforementioned option of integrating a volume flow control. Also noteworthy: The MDM plus has level indicators for both components and can be equipped with the TARTLER mixing head LC 5/3. It can be fitted with rotating disposable mixers, eliminating the need for liquid detergent.

Furthermore, the design of the compact system allows for the use of electric or pneumatic agitators for the components and for the B component to be passed through a silica gel filter. Additionally, the user can perform small recirculations with the MDM plus. In this process, unmixed material is returned to the containers through the pumps and – if available – through the flow meter during dosing pauses. This keeps the operating temperature constant and allows adjustments to be made to the system without material loss. It also prevents filler materials from settling in the dosing hose during material downtime. Regarding container configuration, users have the option to choose containers with capacities ranging from 3.0 to 60 liters. The space requirements and purchase price of an MDM plus are significantly lower than those of a Nodopur system. Therefore, Udo Tartler sees this system as “the ideal solution for resin processors who need to process small to medium quantities in tight spaces and do not want to forgo the advantages of highly efficient dosing, mixing, and application technology.”

Adaptable Small Quantity Systems

Overall, TARTLER offers five small quantity systems in the MDM series. Even the entry-level model MDM 3 features electrically driven metering pumps and container ports for connecting original containers. At a mixing ratio of 100:100, it can output up to 0.7 l/min of material. The largest system in the series is the MDM 6, designed for outputs of up to 3.5 l/min and suitable for containers with volumes ranging from 3.0 liters to 100 liters. Its control allows for large recirculations as well. In this process, the material flows through the mixing head and machine and is immediately ready for use again. TARTLER can customize each MDM system according to customer specifications based on its modularity program – for example, with chassis, refill kits, or heating and degassing systems. “We can accompany a synthetic resin user every step of the way to the next level of machine and automated processing,” emphasizes Udo Tartler.