The new inline inspection system MEDICTUBE-S developed by Pixargus is flexibly adjustable to different materials and tube diameters. The system operates with four cameras, inspecting the tube surfaces completely, objectively and reproducibly. It is now possible for the first time to define precise and mandatory quality standards for medical tubing and to stick to these standards throughout the production process. In this way MEDICTUBE-S guarantees that only completely flawless material is released for sale.

The captured data are used beyond the final inspection of the quality assurance process for optimizing the production process and avoiding defects from the very beginning. For example, trends in the frequency of occurrence of surface defects are captured in real time, so that remedial action can be taken immediately. The operators can directly intervene and promptly sort out defective material.

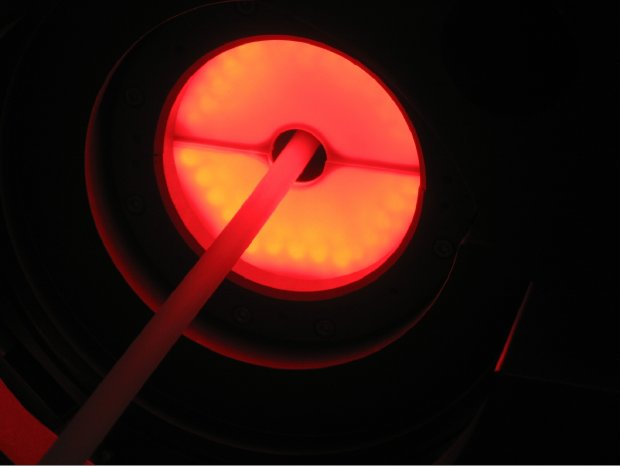

A special challenge in designing the inspection system was the fact that the outside diameters of many of the tubings are very small and defect sizes of less than one tenth of a millimetre have to be detected. At the same time, such tubings are extremely sensitive to mechanical handling. This had to be taken into account in the guiding and threading solution of the system. Pixargus solved this challenge by providing a C-type slot at one side of the inspection unit, enabling the system to be moved into the production line even after the production run has started. The use of extremely high-resolution cameras and a special, split light source make the system capable of making even the smallest flaws visible and detecting them reliably.

Björn Lindner, Managing Director of Pixargus, sees great advantages for both manufacturers and users. “Especially in medical applications 100-percent inspections are an absolute must. At production speeds of 50 m/min and above the human eye is unable to detect extremely small irregularities, above all in a transparent material. Also so-called node monitoring devices, which used to be employed in the past, only measure the outside diameter in two axes. Our new system inspects every individual millimetre of tube from all directions. This ensures that only material of perfect quality is delivered to the customer. But the system also helps manufacturers to significantly reduce their production costs.”

Pixargus is at Fakuma from 10 to 14 October 2008:

Hall A6, stand A6-6115