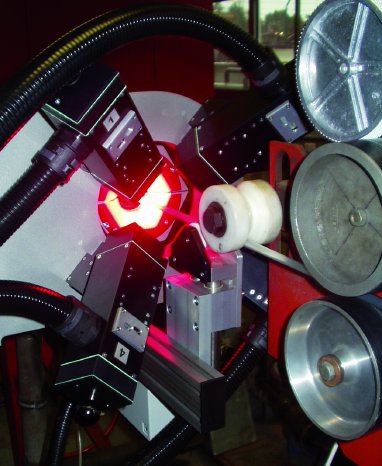

With the new Pixargus “ProfilControl 5-Cable” inspection system introduced at “K 2007” the surfaces of cables can be inspected inline during the production process and over the complete cable length. Up to now cables used to be inspected only in reeled condition, i.e. defects could only be detected in the top cable layers.

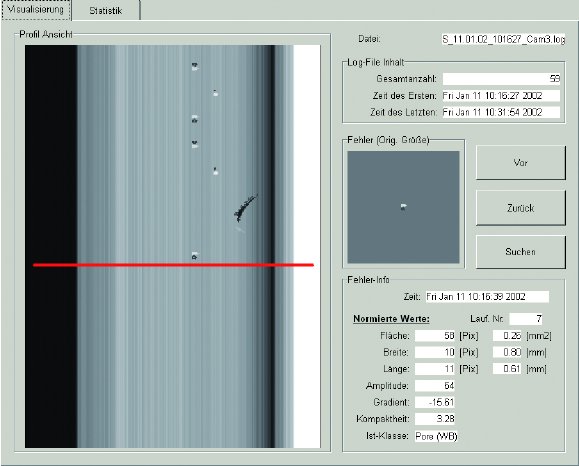

The new system analyzes the surface condition of the jacket and inspects it for holes, fissures, foreign particles and inclusions. Already during the extrusion process, ProfilControl 5-Cable detects flaws on the conductors, the dielectric material or the jacket. The operators can take corrective measures as soon as a tolerance value is exceeded. Out-of-spec material is identified at a very early stage and only 100-percent flawless material is released for shipment. Moreover, conclusions can be drawn as to the causes of surface defects.

Comparable systems offered by Pixargus for the rubber industry have already proven in practical operation for many years. For the cable industry, Pixargus has now developed a dedicated software program, the “Printcheck” module, which is for the first time presented to the public at “K 2007”. This module is capable of detecting printed characters on flat ribbon cables, reads the printed letters and numbers and checks whether the print matches the input text. The module also checks the appearance of the type. Distorted letters or ink marks on the cable surface immediately trigger an alarm. A plausibility check guarantees that always the right and correctly labelled material is dispatched.

According to Björn Lindner, Managing Director of Pixargus, the new system provides a number of important advantages over the technology used so far. “In the past we lacked inline inspection technology capable of checking the complete cable surface by more than just one criterion. So-called node monitoring devices used in the inspection of round cables only measure their outside diameters in two axes. This is definitely not sufficient to produce the quality our customers demand today”, explains Lindner.

ProfilControl 5-Cable is laid out for maximum production rates of 400 m/min. Due to its compact design – it requires an installation length of only 300 mm in the direction of the production flow – it can be easily integrated in the production lines. Depending on where in the production chain the sensor is installed, ProfilControl 5-Cable inspects the surface of the conductors, of the cable cores, the dielectric material or the cable jacket.

The system is suitable for round indoor and outdoor cables, power supply and telecommunications cables, symmetrical and/or coaxial data and communication cables in copper or optical fibre design as well as flat ribbon cables. It works independent of the material. Surfaces of PVC, PE and PTFE are inspected just as reliably as non-halogenated compounds.

As the Sales Manager of Pixargus, Dirk Broichhausen sees above all the advantages for the customers. “Increasing output rates, decreasing reject rates, less complaints and minimized process costs – all these benefits make for a very fast return on the investment.” According to Broichhausen, also downstream random product checks and testing shop activities, for example spark testing of the cables, become superfluous.

Like all Pixargus systems, ProfilControl 5-Cable is characterized by simple intuitive operation via touchscreen and clearly structured process data visualization. On request the system can be supplied in an extremely compact panel PC design.