Consistent thanks to "Single Source of Truth"

"The various aspects of project planning have previously not been sufficiently networked on the tool side. EB's library-based approach and consistency are now helping to increase networking," says Matthäus Englbrecht, Vice President Global Brake Systems at Knorr-Bremse. Pneumatic and circuit diagrams as well as BOMs now have a "single source of truth" for all components of the braking system.

"By allowing the various departments involved to all access EB's joint database, their cooperation is also further improved," says Englbrecht. The cooperative platform replaces two systems at Knorr-Bremse. It covers both the mechanical and the control technology aspects of systems engineering. Pneumatics, electrics and electromechanics are only different views of the same database.

According to Englbrecht, this integration of different areas also helps the platform to increase data quality and reduce interfaces as well as manual work, possible transmission errors and manual checks. The connection to the Windchill product lifecycle management system used by Knorr-Bremse also supports these benefits beyond the EB system boundary. For example, by automatically making available the work results to all departments along the value chain.

Modularity needs central data

"In addition to the networking capability, it was crucial for us that EB could map the modularity of our brake systems," adds Englbrecht. EB's central library is an important basis for this. "In our decision-making process, we took a close look at the market and Aucotec's references," continues the division manager. "Initial pilot projects have confirmed our conviction that the various engineering departments can move further together and work more integratively with this solution. For this, we are working with Aucotec to further improve the integration of EB into our processes and Windchill."

"Important pillars for Industry 4.0"

For Aucotec, an independent software developer for over 35 years and one that has grown considerably in recent years, the collaboration with Knorr-Bremse is an important confirmation: "EB's concept of networking and modularization meets modern engineering requirements exactly. Both are important pillars for Industry 4.0 and future-oriented efficiency. We are therefore very pleased to have convinced such an innovative, successful company," explains Uwe Vogt, Member of Aucotec AG Management Board.

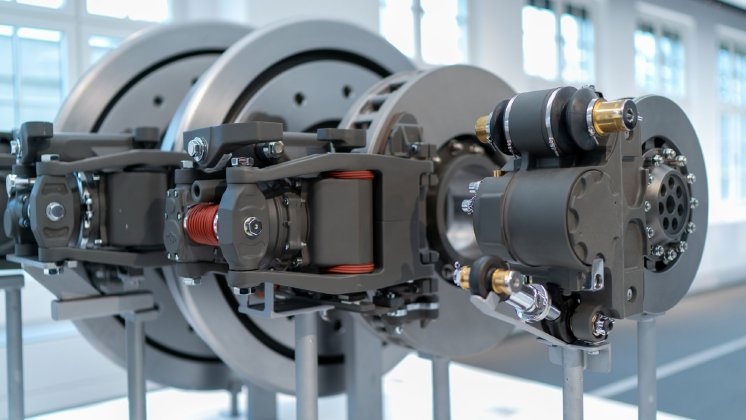

Knorr-Bremse is the world market leader in brake systems and a leading supplier of other systems for rail and commercial vehicles. Knorr-Bremse products make a significant global contribution to greater safety and energy efficiency on rails and roads. Around 29,500 employees at over 100 sites in more than 30 countries apply themselves with competence and motivation to satisfying customers worldwide with products and services. In 2020, Knorr-Bremse generated a global turnover of EUR 6.2 billion (IFRS) in its two business divisions. For more than 115 years, the company has been driving developments in mobility and transport technologies as an innovator in its industries and has a head start in the field of networked system solutions. Knorr-Bremse is one of the most successful German industrial groups and benefits from the important global megatrends: urbanization, sustainability, digitalization and mobility.