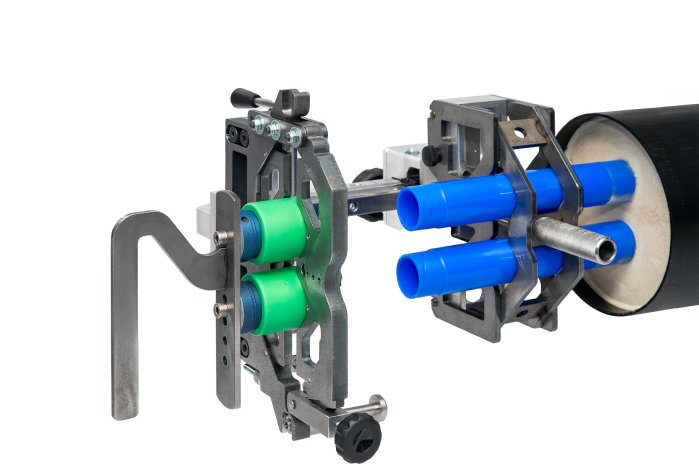

Thanks to the integrated twin system, not only is the excavation volume reduced - installation time is also significantly shortened. The lightweight plastic pipes greatly simplify handling on the construction site, especially compared to heavy steel pipes. A socket welder, specially developed in cooperation with Ritmo SPA, ensures a particularly simple and fast connection: both medium pipes are welded simultaneously in a single step – saving up to 50% of the time compared to conventional methods. The weld seams are manufactured synchronously and automatically monitored – delivering maximum process reliability with minimal effort. This solution is unique worldwide and sets new standards in plastic welding technology.

Future-proof for 4th generation district heating

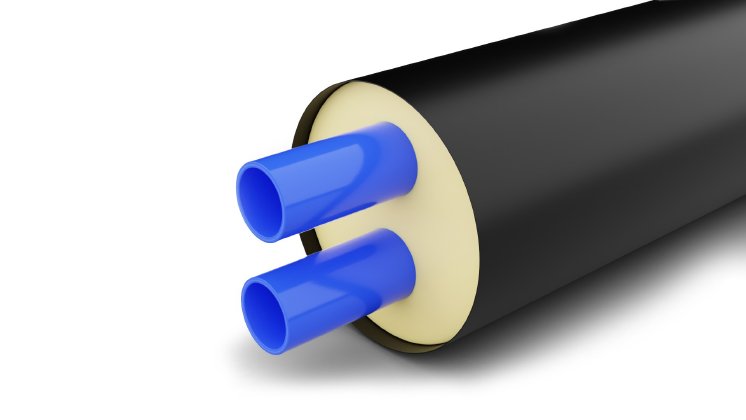

aquatherm energy twin is optimally adapted to modern district heating systems. The pipes, made of polypropylene (PP-RCT), are lightweight, corrosion-resistant, and particularly temperature-resistant (permanently up to 75°C, and briefly up to 100°C). High-quality PUR insulation, in accordance with DIN EN 253, along with a robust PE casing, ensures maximum insulation performance and protection. An integrated OT barrier layer reliably prevents oxygen ingress – supporting long service life and high operational reliability.

The system is available in sizes ranging from 32 to 125 mm. For larger requirements, aquatherm offers single pipe solutions up to 450 mm. All variants are also available with leakage monitoring, enabling early leak detection and helping to minimise water loss, environmental impact, and potential operational failures. This reduces maintenance costs.

Result:

With aquatherm energy twin, aquatherm expands its proven aquatherm energy family with a twin-pipe system that makes installation remarkably simple – quick, reliable, and efficient.

For more information, see https://www.aquatherm.de/...