True to the motto supply, connect, distribute the "CH20M" electronics housing system allows development engineers and designers to deploy an optional mounting rail bus. The universal mounting rail bus is a userfriendly infrastructure solution to crossconnect and network power, signals and data. Representing an uninterrupted and flexible system solution integrating the bus in the mounting rail replaces costly individual wiring. It reduces wiring work as well as the associated susceptibility to faults. Redundant functions can be efficiently centralised or distributed intelligently in complex applications.

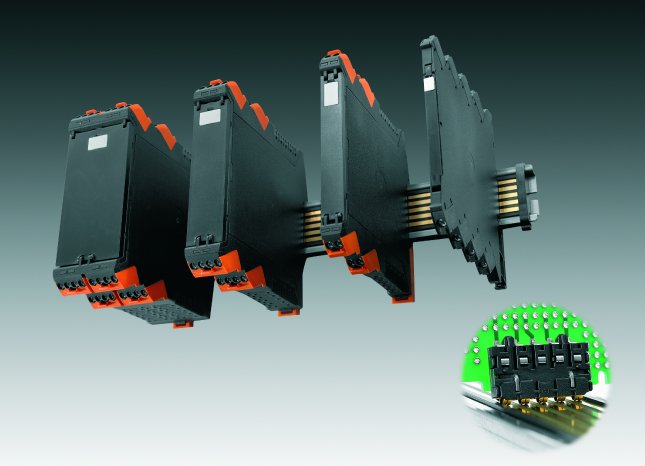

The system bus is designed to be securely integrated in standard 35 mm mounting rails. It supports freedom of configuration and individual module placement on TS 35 x7.5 or x15 mm tophat rails to DIN EN 60715. The new bus connection allows all modules of the "CH20M" family of housings to be crossconnected and networked; and it goes without saying that this compelling feature applies to all housing widths - from 6 mm to 12.5 mm through to 67 mm. This is a unique design feature. None of the other housing systems based on a mounting rail bus system available on the market today can compete. Weidmüller has designed its "CH20M-BUS" to be installation and service friendly, which means each module can be replaced quickly if the need arises. Straightforward replacement does not require that the entire group has to be taken apart. The individual modules are simply swivelled in and out of the module group.

The contact block of the "SMD-Bus" has five conductor tracks - two power tracks, a signal track as well as two data tracks, each rated to 5 A respectively. The bus contact block is made of the highly heat resistant plastic LCP (Liquid Cristal Polymer), a material that offers excellent dimensional stability - in particular at high temperatures. LCP is similar to the material from which circuit boards are made. Its extremely low thermal expansion coefficient means this plastic is suitable for the SMT reflow process. The "SMD-BUS" contact block is supplied ready for automatic placement and can be processed fully automatically together with the component group in a single SMT manufacturing process. THR solder flanges on the bus contact block ensure a stable connection with the component group PCB.

The concept underlying the "CH20M-BUS" mounting rail bus system is geared towards reliability. Five fully electroplated and partially gold plated, rounded twin contacts ensure reliable contacting between the contact block of the "SMD-BUS" and the mounting rail bus. The conductor tracks of the mounting rail bus are also gold plated - ensuring troublefree application operations. In contrast to plugin bus systems this seamless assembly concept avoids contact resistances and undesired disruptions to the bus. The resilient, goldplated contact surfaces guarantee a permanent and reliable contact across all housing widths. The system bus can be integrated in all 35 mm standard mounting rails of standard heights (7.5 and 15 mm).