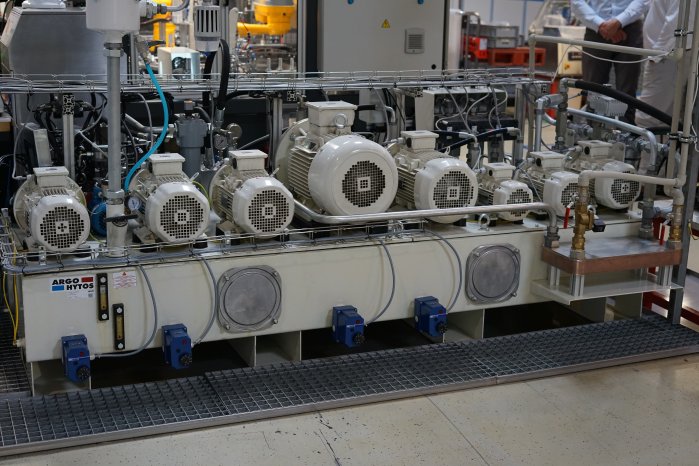

Argo-Hytos set automation partner and system integrator Resim the clearly defined task of automating to the maximum extent a previously manual production line for electromagnetic valves at its plant in the Czech Republic.

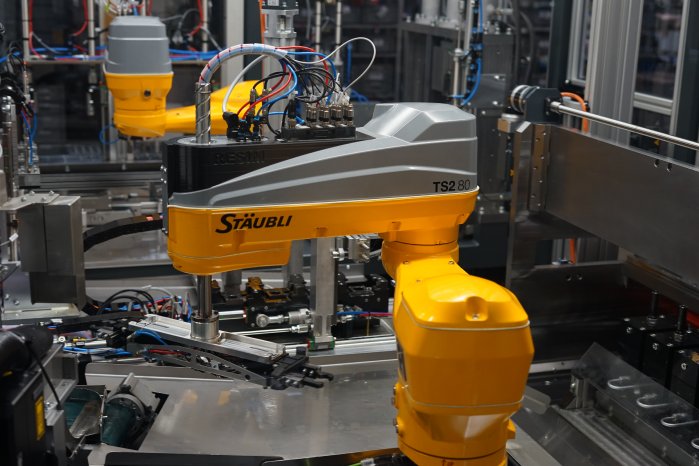

In planning the project, the Resim team of designers was not only able to draw on the experience gained from the company’s long and successful collaboration with Argo-Hytos, but also on the expertise they had acquired over 30 years of industrial automation. An essential component of this know-how has been the recognition that, when precision and speed are the main criteria, Stäubli robots are the first choice.

In this case, four TS2-80 SCARA robots take on the handling of the electromagnetic control valves during assembly and subsequent end-of-line testing. There are several good reasons for this. With a TS2-80, the system integrator can theoretically perform up to 200 gripping operations per minute. This corresponds to a cycle time of 0.33 seconds while maintaining high precision: Repeat accuracies of up to ± 0.004 mm in the Z-axis are possible for pick and place.

The robots in the new assembly line supplied by Argo-Hytos do not have to work to quite that degree of accuracy, but the demands in terms of precision are nonetheless high. After all, the valves are pressurized to several 100 bars when in operation. The assembly of the individual components and especially the seals must be correspondingly precise.

Challenge: Automated valve testing

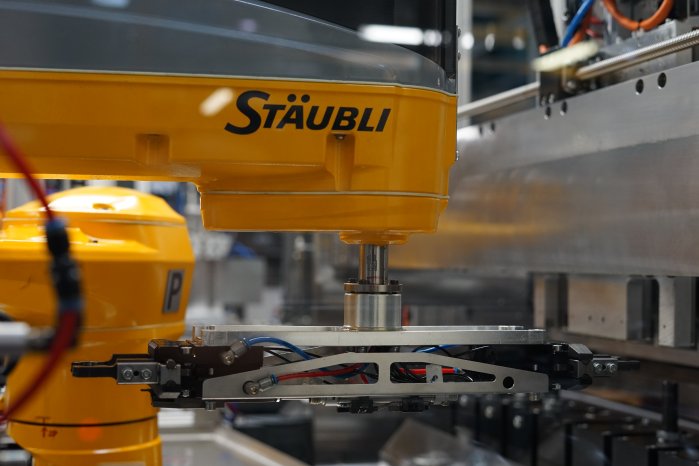

Automating the end-of-line test station proved to be particularly challenging at the project planning stage. Argo-Hytos developed its own testing device for this task, and this is where an unexpected obstacle arose. Screwing the valves into the test station caused no problems for the TS2-80. When unscrewing, however, the final turn on the thread occasionally jammed, bringing the test station to a standstill.

Solution: Force measurement on the fourth robot axis

The experienced Resim designers were soon able to solve this problem by bringing into play the design feature of Stäubli robots that permits integrated force measurement – without external sensors – on all four axes. In this specific case, the force is measured on the fourth axis, which allows the system’s control unit to recognize whether the valve is turning freely in the internal thread of the test unit. If the measured force increases, the obstruction can be overcome by briefly reversing the rotary movement. If necessary, the process can be repeated several times.

This ensures that the valve does not jam and the system does not come to an unplanned stop. The great advantage here is that the force measurement function is integrated into the drive system and therefore no external sensors are required.

Conclusion: Good collaboration leads to a successful project outcome

From the point of view of all those involved, the collaboration between Stäubli, Argo-Hytos and Resim on this project was highly productive and goal-oriented. The production line was up and running in spring of 2022 and, more than two years later, it is still working just as efficiently as the day it was first installed. Argo-Hytos has achieved its objective of fully automating the complex final assembly process of electromagnetic hydraulic valves. The valves meet the highest quality requirements, and the Stäubli team is proud to be part of this successful collaboration, which will certainly not be the last of its kind.

Text by: Ralf Högel