The machines from the Xtra series have hardened cutting tools made of high quality steel. This guarantees a long service life even when processing abrasive plastic materials.

Metal impurities in sprues can nevertheless cause damage to the cutting chamber. In order to reduce impurities and thereby costs, Wanner was looking for a metal detection solution for the inhouse recycling of plastic sprues. The metal detector should be especially suitable for the Xtra series and easy to sell for Wanner´s sales network.

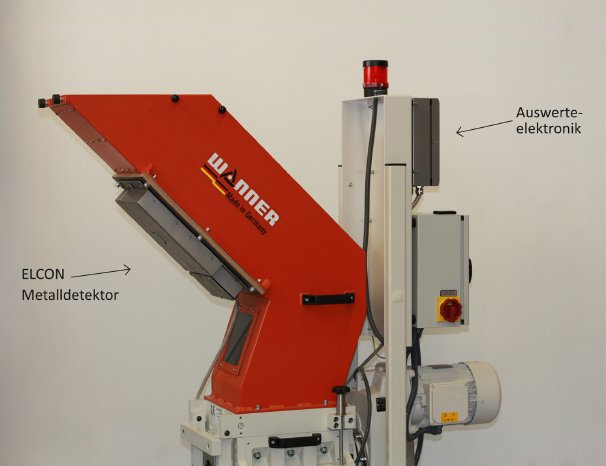

Cutting unit safe protected

Wanner opted for the plate type metal detector ELCON 250 from Sesotec GmbH, since a successful cooperation between the two companies existes already for a long time. With this metal detector are the cutting tools of the granulator safely protected against damage because ELCON detects all magnetic and non-magnetic metal impurities before even touching the cutting chamber. The used half-wave technique stops the crushing tool when metal detection occur and thus prevents the introduction of metallic impurities into the further manufacturing process. In addition, false rejects caused by vibrations in the crushing of brittle plastic materials and hard sprues are minimised.

Carsten Weidel, Regional Sales Manager at Wanner: „What we particularly appreciate about Sesotec is their support on site and the precise implementation of our specifications from Sesotec´s development department. Our customers who use Xtra granulators benefit from the metal detection solution by reducing costs related to machine repair or production stops.“