Sensors from Sensitec provide clear information about the status of moving, mechanical components or about the electromagnetic identification of motors or other machine elements. It is even possible that the sensors fulfil two functions simultaneously. In addition to the standard angle, position or current information they provide further data about the condition of the machine.

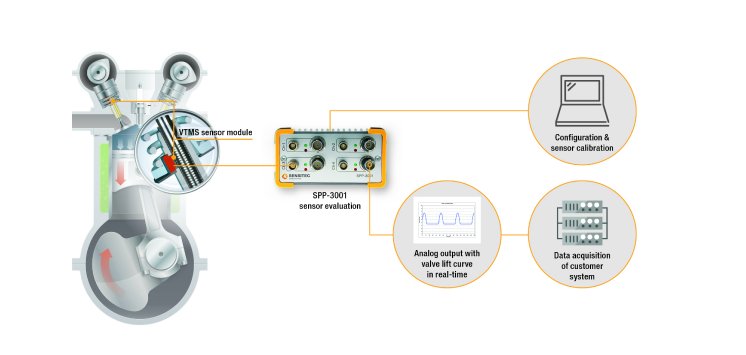

A typical application example of a robust xMR sensor solution is to measure valve lift or valve rotation directly in fired combustion engines under real operating conditions. This is one of the most demanding measurement tasks when developing or improving components of combustion engines. Until now the valve behavior was measured by means of simulation or using an electrically-driven dummy engine, i. e. the measurement was not carried out under real operating conditions and did not reflect all thermo- and fluid dynamic effects that affect a real valve train. The Valve Train Measurement System (VTMS) from Sensitec has been developed for the precise length measurement at difficult measuring sites within fired combustion engines. With the development of the new VTMS modern GMR sensor technology combined with a powerful evaluation electronics is able to solve a highly complex measurement task by means of a surprisingly simple and effective measurement solution. The GMR sensor features a bias magnet which scans a ferromagnetic measurement structure machined into the valve stem. Since the valve stem is precisely manufactured it is ideally suited as measurement scale. The subsequently applied mechanical structure has no impact on normal valve operation. Valves are normally made of ferromagnetic material. However, non-magnetic variants (e. g. titanium) can also be used as measurement scales, however, this requires some additional minor modifications. Since the sensor is very precise and exhibits negligible hysteresis the measurement accuracy is better than 10 μm. The measurement accuracy is equivalent to that achieved by laser-based measurement systems. Initially the VTMS was developed for a direct measurement at the valve shaft. Nevertheless, it is no problem to use it for other applications, especially when precise measurement is required in small envelopes or under extreme conditions, for example, for measurement inside gearboxes.

Sensitec now offers a completely new evaluation unit for the valve train measurement system. The experience acquired with the original and successful single channel system has made a contribution to the development of this new device and many customer requirements have been implemented. The new unit (SPP-3001) is extendable up to 32 measurement channels, provides a higher resolution and offers better measurement comfort. The existing user interface has been completely revised and updated: A new look, extended features and more measurement functions are available. The system also now supports some additional sensors from Sensitec, such as speed sensors, to allow simple correlation of valve position with cam- or crankshaft position.

Compared to the previous model the SPP-3001 provides a considerably higher sampling frequency (1 MHz). The valve position is detected with a resolution of better than 1 μm and the position value is given in real time as an analogue voltage. The system provides a reliable measurement of rapid valve motion. The maximum lifting movement has been extended and the functionality to measure the valve rotation is completely integrated. Depending on the number of channels different housing systems are available. This simplifies the mechanical integration into the existing environment.