With the Schüco CC 800 corner crimping machine, fabricators benefit from a fully automated punching process suitable for a wide range of profile geometries. Thanks to the machine's high process reliability, a frame can be fabricated every 70 seconds. Manually fed frames with a profile height of up to 250 mm are punched precisely and fed out. Even profiles with a pre-inserted gasket can be processed with ease. Operation is particularly user-friendly thanks to the simple controls via SchüCal, combined with data entry using barcodes or matrix codes. The corner crimping machine also features integrated, fully automated profile tolerance compensation. What's more, the CC 800 also makes it possible to easily process profiles with a difference in height without the need for special blades.

Flexible use

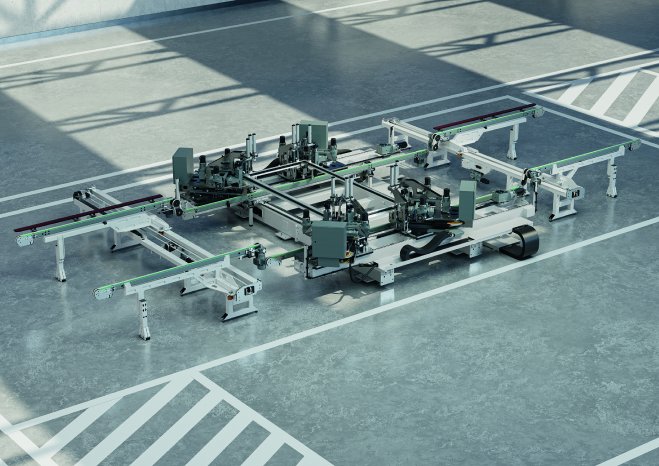

The CC 800 can be used in a variety of workshop layouts and is particularly suited to production line manufacturing, whether for window, door or façade units. Preventive maintenance, supported by logbook entries and pneumatic monitoring, also ensures the machine's longevity and reliability.