- Own-production diamond wire features best performance data and is a genuine alternative to the product of the market leader

- The entire machine portfolio is now prepared for diamond wire-cut wafers

- SCHMID accompanies production change-over and takes care of downstream processes

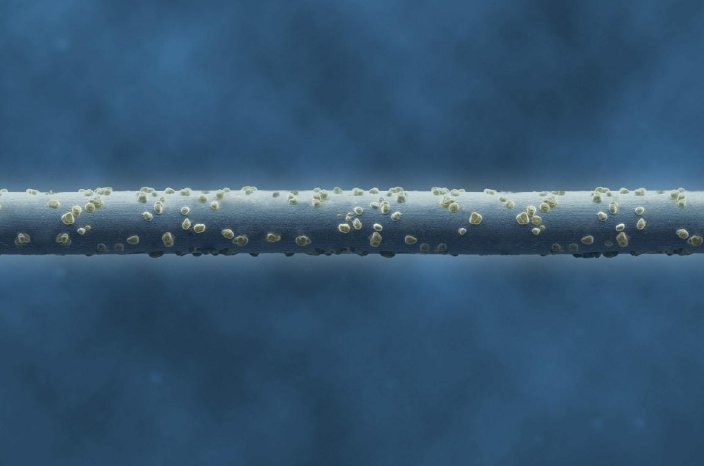

The wafers of the future are getting thinner and thinner and already approaching a thickness of 140 μm. The slurry sawing process in mono-crystalline wafer production is therefore facing being replaced by the diamond wire based sawing process. The advantages of this new process lie in the almost parallel profile of the saw cut and a smaller kerf width, which saves valuable raw material.

The SCHMID Group has now prepared its entire product range in the Wafer business sector for diamond wire based wafer production and offers in addition to systems for wafer cleaning, singulation and inspection, their own diamond wire and a wide range of services connected to the sawing process. At the Intersolar Europe in Munich the diamond wire met with a good response due to the excellent results achieved by the tests carried out so far which actually beat the market leader in thickness variation (TTV).

"We regard this as a very good moment to introduce the product. All important market participants are looking for solutions for optimizing the costs of their wafer processes" explains Reinhard Huber, Vice President of the SCHMID Group's Wafer business unit, whose sales team markets the entire product range of the diamond process. "The diamond wire offers the basis for saving costs. Particularly in the rapidly growing market of mono-crystalline wafers, this wire is the generally recognized means of producing wafers in future which are not only thinner but also have a higher parallelism of the surface (TTV)"

The diamond-studded sawing wires of the FK series, which are manufactured by the Japanese SCHMID Group member Facility, have already been tested on conventional wafer saws and are distinguished by their small diameter and their controlled, consistent diamond concentration. Customer feedback so far confirms high feed speeds, low abrasion and a small kerf.

SCHMID's strategy has thus proved to be a complete success. The great market potential was evident already at the beginning of the three-year development phase. We are convinced by the advantages of diamond wire which has already proved itself in Japan" explains Kazuyuki Kishi, CEO of Facility. The next phase is the worldwide marketing, whereby the main focus will be on the Asian continent.

All technical challenges of a production change-over to the diamond wire sawing process are being accompanied completely and competently by the SCHMID Group in the core processes of Sawing, Cleaning, Singulation, Inspection and Texturing. Here they can fall back on comprehensive know-how from customer projects and their own Test Centers.

To ensure the the continual development of the diamond wire sawing process, SCHMID signed a cooperation contract in May with the globally operating and independent institute, Fraunhofer CSP in Halle, Germany.

About Facility

Facility Co., Ltd. (Japan) is a member of the SCHMID Group, producing customer-specific systems for the PCB industry. Their successful processes and systems developed for the production of diamond wire for the PV industry are backed by many years of experience and specialized know-how in the field of plating technology.