Calculation of rolling bearing rating life – what does this involve, and why is it so important for the user?

In addition to the static load safety factor and design envelope, the calculated rating life is the central parameter for designing rolling bearings. In most applications, the bearings are dimensioned according to the rating life requirements. There are many areas, including the wind power sector, in which certification only takes place if the calculated rating life is above a minimum value that is required by the relevant standards. The demand for energy savings means that downsizing is now sought-after in many applications. It is important here that, even when smaller bearings are used, the rating life requirements are fulfilled with a reliable rating life prediction.

Quality – worldwide and permanent

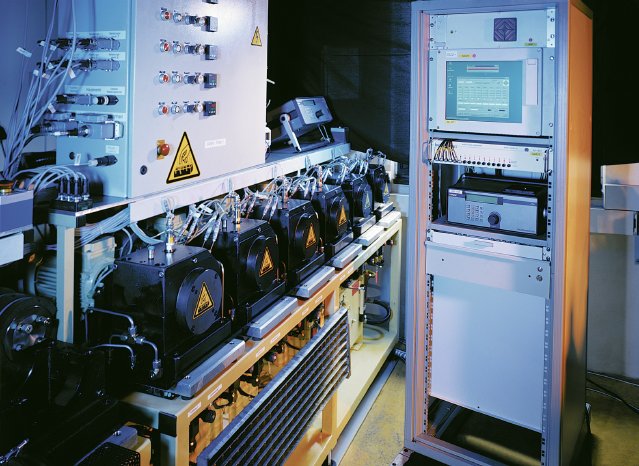

During the certification process, Germanischer Lloyd was convinced that Schaeffler can permanently ensure the rating life factors that are determined during product development worldwide. It was also proven that the tested material and process quality is valid not just for the test parts but for the entire series – worldwide. All of Schaeffler's rating life test centers – which in addition to Herzogenaurach and Schweinfurt also include Kysuce in Slovakia and Taicang in China, for example – now proudly display the prestigious seal of approval.

Schaeffler manufactures to the same high international standards worldwide. The basis for this is provided by its company-wide quality management system, whose many benefits include a constantly ensured level of material and process quality. State-of-the-art manufacturing technology for precision products represents a significant contribution to “zero-defect manufacturing”. Here, quality monitoring is integrated directly into the manufacturing process as a closed control loop. Regular audits are carried out in all areas to ensure a high standard of quality.