His fields of specialization include electrical systems and data transmission solutions. “ODU has demonstrated top expertise and quality in connector systems and the develop-ment of innovative connector technology for over 75 years now,” says Rudolf Dechantsreiter. That’s exactly the same kind of expertise we need for designing eMobility concepts for the electrical systems of the vehicles of tomorrow.

With our focus on trends in the areas of urbanization, environmental protection and tailored customer solutions, we’re concentrating on future developments in high voltage applications.

Novel materials and assembly concepts for increasingly complex modules – these must be developed even more quickly while at the same time being space-saving and lightweight, and ensuring 100-percent functionality and reliability.

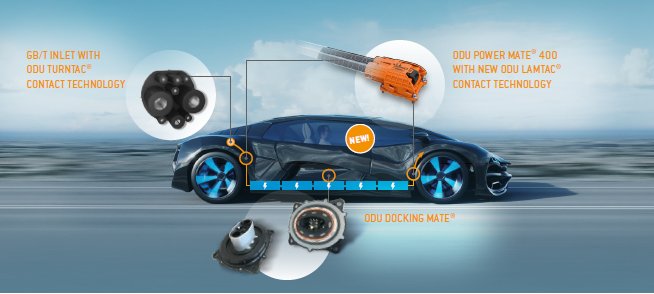

With the ODU POWER MATE® 400, ODU developed a new high-voltage connector that connects the electronics of the e-vehicles with the storage battery.

Its space-saving design and compact locking system make it an intelligent solution for high-voltage connector systems. It goes without saying that the plastics in this connector all meet fire protection class V0.

- Compact design

- Innovative locking mechanism

- High current carrying capacity

- 2-pole HV connector system

The new connector is attracting growing interest in such application areas as high automation levels and quick battery changes in industrial production, driverless transportation systems in warehousing, or future autonomous passenger transportation systems with separately changeable drive axles.

- Self-finding docking of HV-battery & drivetrain modules

- Tolerance compensation up to +/–5 mm

- Highest ampacity levels up to > 400 A, scaleable