Visionary concept

First of all the engineers prepared a specification sheet, including load capacity, motion axes, strokes and operating range. According to this the development and manufacturing of the CE marked lifting tool began. After intensive tests of the automatic solution the engineering team transferred the overall concept to customer-specific handling tasks.

Lifting tool HT2 - easier to handle

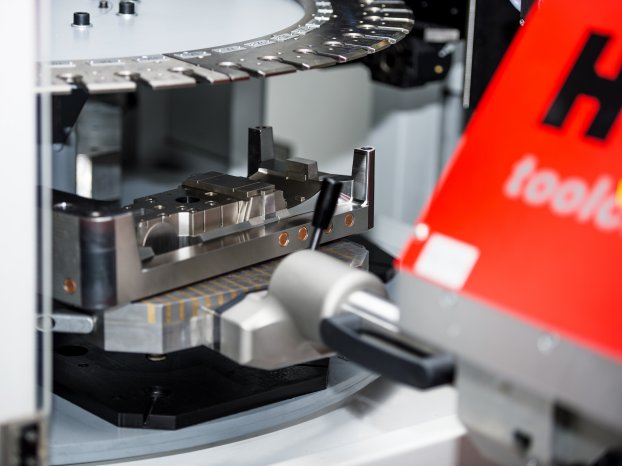

Originally invented as an internal means of work facilitation at Toolcraft, the lifting tool has become a sought-after product. Testing the motorized tool in the own automated mould making plant showed valuable insights for further optimization. The lifting tool HT2 is characterized by its technical redesign as well as a crucial reduction in weight - and is therefore easier to handle.

Manoeuvrability in all directions

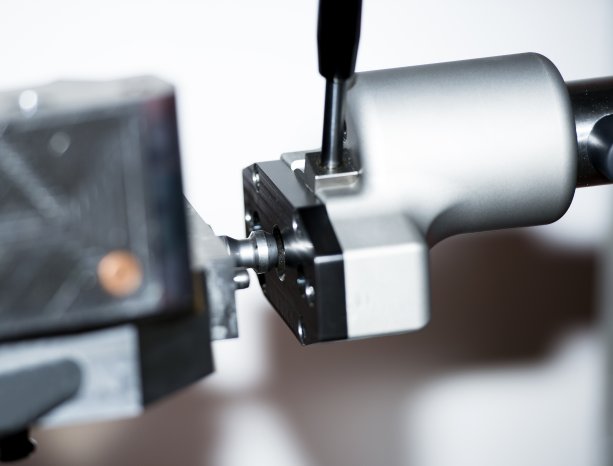

"The lifting tool HT2 is a revolutionary solution", says Thomas Wieland, team leader engineering at Toolcraft. It is 1, 3 m long, almost 2m high and about half a meter wide. The tool has a battery-powered Z axis and free-floating X and Y axis with a turning axis A. These allow a rotary of 100 degree as well as a fine adjustment. A battery serves as power source and lasts for 200 lifting processes after it has been loaded totally. The lift height is between 265 und 1490mm and can be passed with 20 mm/s as well as more slowly with 5 mm/s. The total weight of the lifting tool is 380kg. Furthermore parking brakes provide a secure and safe standing position. Monitoring while putting down the plates - i.e. an automatic shut down - prohibits too much pressure on the machine table. The clamping system is actually an EROWA system. Upon request other systems are available.

An absolutely unique solution

With its competence for solutions, Toolcraft has developed an absolutely unique lifting tool, although initially not conceived for sales. The Tool can lift and transport heavy loads up to 120kg easily and lift heavy mould plates in machine tools easily. The lifting tool HT2 is another example of the passion for innovation at Toolcraft.

Facts about the lifting tool HT2 – an overview

- length: 1375mm

- width: 690mm

- height: 1980mm

- weight: 380kg

- lift height: 265 – 1490mm

- workload: 120kg

- rotary of 100 degrees

- fine adjustment in X and Y

- battery-powered Z axis

- parking brakes

- clamping system EROWA (upon request other systems available)