Automating production flows

"Robotics technology has a long history of development. At first, the technology was primarily used in the automotive industry. However, robots can now be found in almost every sector,” explains Thomas Wieland, team leader robotics at toolcraft. Nevertheless, the optimal way to chain individual production stages in a logical order must be explored. This is how automated solutions in areas such as metalworking and plastics processing, wood and model construction, as well as material finishing are developed. Machining, grinding, drilling, cutting as well as deburring, polishing and measuring are all possible depending on which robots are used. The 3D simulation software now even does away with the need for complicated physical tests. The software makes it easy to visualise the automation of several process steps, simply by entering all the parameters.

3D simulation software can be extended flexibly and without limits

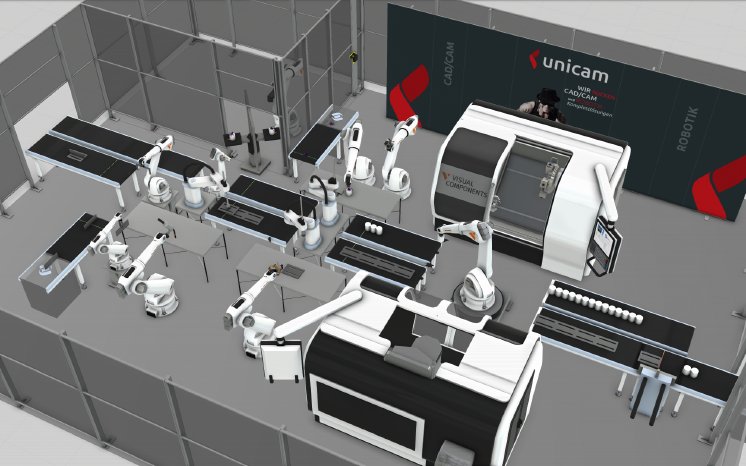

Visual Components can be used to plan entire production halls and simulate production flows using one or more robots. This enables toolcraft to determine cycle times in advance in order to avoid any collisions. The new version displays the movements of cables, conveyor belts and other items in an even more realistic manner. A continuous platform links visualisation and 3D simulation, robot programming and simulation of material flow and resources. The manufacturer's library currently contains robots from over 30 different manufacturers and around 2,000 components. There is also the option of adding the company's own machines via CAD interfaces. This enables the software to be extended flexibly and without limits. It is an excellent sales tool, particularly for systems integrators. For example, within a relatively short amount of time, it can be used to create a production line with numerous details in a 3D PDF.

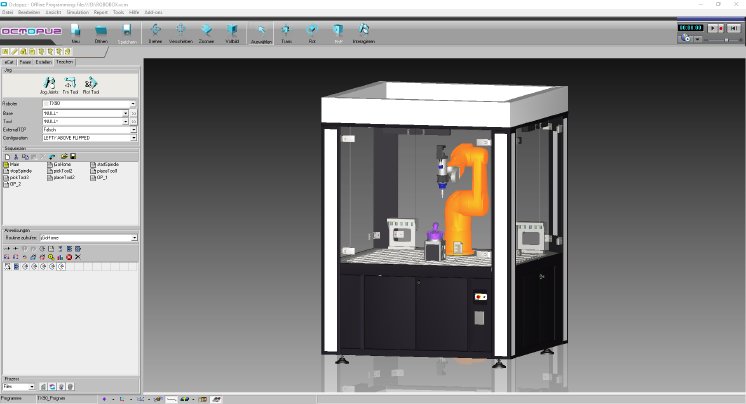

Offline programming with Octopuz

When it comes to implementing the robotics solution, toolcraft uses Octopuz offline programming software. This is based on Visual Components. toolcraft's long-term cooperation with the unicam software company is particularly valuable in this regard. The software is suitable for every path-sensitive robotic application and is therefore capable of being used in a variety of ways. The user can simulate all the components in a cell as well as multiple robots at the same time offline. "Its versatility makes it ideal for every industry that uses robotic production technologies. The program is also adapted to meet customers' individual needs," explains Johannes Krebs, managing director of unicam. This not only enables the automation of production processes to be stimulated, it also enables them to be implemented accordingly.

About unicam:

Since 1992, unicam Software GmbH has been the systems partner for CAD/CAM complete solutions. The systems company provides the highest level of production support in milling, turning, wire cutting and robot processing. As an authorised dealer of the globally successful products Mastercam, SolidCAM and Octopuz, the company sets its customers on the right course for the future. With its many years of experience, unicam provides its customers with professional, personalised support through its own post-processor programming and training courses held in the company's own building.