A wealth of advantages over conventional manufacturing methods

Metal laser melting can be used to manufacture complex and efficient lightweight structures as well as internal structures. This means the technology is especially beneficial for the aerospace, energy, medical engineering and motor sports industries. It enables entire processes to be reinvented from scratch and has a host of advantages over conventional production methods. These are especially evident when manufacturing extremely complex parts needed quickly and in small quantities. The technique also allows last-minute design changes to be implemented quickly and easily, and is even capable of producing parts up to 30% lighter in weight than conventionally manufactured components. What's more, it can be used to manufacture previously complex groups of components as a single piece following a few small design tweaks. This is not only more cost-effective, but avoids the need for once crucial joining techniques to be applied.

Continued expansion of additive manufacturing

As a pioneer in additive technology with more than 15 years' experience, TRUMPF manufactures robust and reliable machines for industrial series production. The company offers both of the laser technologies relevant to additive manufacturing – laser metal fusion and laser metal deposition. In order for the process to be used in an industrial setting, TRUMPF provides a comprehensive range of solutions comprising digitisation, machines and services. toolcraft has set up the entire process chain in house – from design, manufacture and refinement using machining techniques, to quality control and non-destructive testing in accordance with NADCAP requirements.

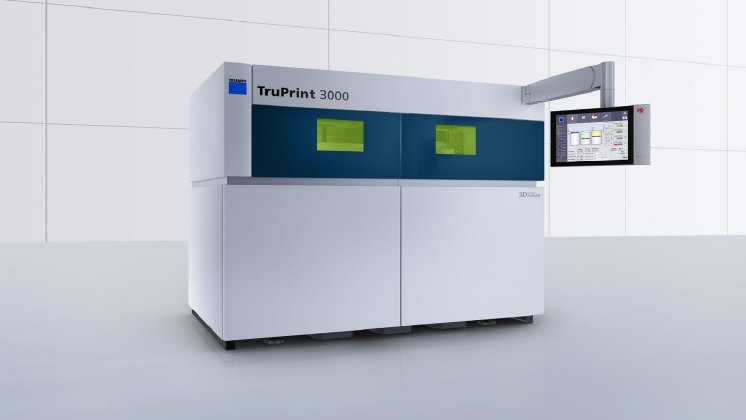

"We decided to purchase the TruPrint machine in order to spur on developments in the area of additive manufacturing," says Christoph Hauck, Managing Director of toolcraft. With this endeavour in mind, the company is constructing its own laser melting centre with a production area of 800 m². "We are delighted at toolcraft's forward-looking decision to implement and help drive forward the use of additive manufacturing in industry by purchasing the TruPrint 3000 with its industrial part and powder management features," comments Daniel Lichtenstein, Head of Sales and Market Development at TRUMPF's Additive Manufacturing division.

A trailblazing investment

The TruPrint 3000 is used for the series production of complex, metal components. It offers considerable flexibility in terms of the size, number of parts and geometry of the components it is used to produce. The interchangeable cylinder principle reduces set-up times, increases productivity and machine utilisation rate, and ensures a clean, powder-free production run. Meanwhile, additional time is saved thanks to the simultaneous LMF, powder and parts processes. Production is further optimised by intelligent monitoring solutions and consistent software.