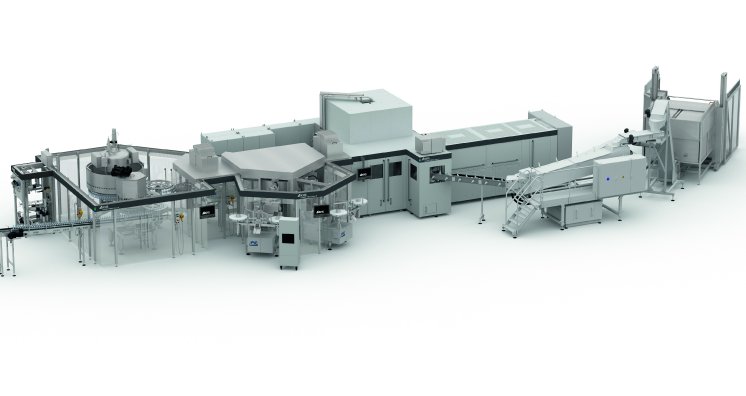

“With this system we’re offering more than just the compact version of the single machines. With the KHS InnoPET TriBlock Aqua M our customers get real added value,” says Arne Andersen, global product account manager for the TriBlock at KHS. The new system blocks the further developed Blomax Series IV stretch blow molding module, a labeling module and the Innofill PET NV filler. Together they form a unit which is perfectly suited to the application on hand, manufacturing bottles from preforms and then labeling, filling and capping them. Further advantages of the machine according to Andersen are its exceptionally hygienic design and optimized housing. The machine is centrally controlled by the improved HMI (human machine interface) on a clear 21.5-inch monitor with full HD resolution for detailed visualization of the process graphics. Another aspect which is especially important for practical operation is the consistent drive and operator concept with which KHS boosts effectivity and the level of convenience.

Optimized process steps

The individual modules on the TriBlock give optimum performance at every stage in the process. Compared to the previous model, the further developed Blomax Series IV has blow stations on which small bottles with a maximum diameter of 75 millimeters can be blown. The low level of noise pollution also deserves a mention here, this ensured by the aforementioned InnoPET Silent TipTainer; with its closed system and lower PET preform drop height the latter are fed especially gently and thus less noisily to the sorting unit.

The labeling module is distinguished by its robust design and thus a high degree of reliability and availability. A special vacuum system permits materials of a very low thickness to be used for the bottles and thus helps to cut costs. In addition, the top-drive technology, which consistently feeds the bottles through the TriBlock by their neck rings, also has many benefits: it is gentle on the PET bottles, minimizes downtimes and is advantageous when making lightweight containers as these are no longer exposed to any compression force in the labeler.

Low maintenance effort cuts costs

A new generation of valves in the filler shortens the filling time so that fewer valves can be used for the same total filling capacity. By focusing on smaller bottles and through the subsequent reduction in pitch, the diameters of both the filling wheel and ring bowl have been decreased. This makes both the filler and the TriBlock as a whole more compact. Users profit from a reduced maintenance effort and cuts in maintenance costs.