Opticline CA Series with Robot Loading

The optical measuring systems in the Opticline CA series are particularly suitable for flexible automation solutions. They are extremely robust and specifically designed for long-term use in tough production environments. The optical measuring systems measure the size, shape and position of shaft-type workpieces, such as motor and transmission shafts, turbochargers, valves and pistons, with the utmost precision and reliability during the manufacturing process. The optical measuring systems are non-contact and perform measuring cycles in a matter of seconds. Standardized hardware and software interfaces allow the systems to be integrated seamlessly and flexibly into automated production processes. The new Tolaris Optic measurement and evaluation software allows simple programming with a graphical user interface and intuitive functions that are focused on measuring tasks.

The solution presented at the EMO trade fair is a compact unit comprising handling robots with workpiece storage and the Opticline CA618 optical shaft measuring system. It was designed and created by Jenoptik in cooperation with RoboMAX from Blumberg in the Black Forest region of Germany.

Waveline Wavemove: Fully Automatic Roughness and Contour Measurement

The Waveline Wavemove measuring systems allow individual, CNC-controlled, fully automatic roughness and contour measurements to be performed directly at the production line. Up to eight independent CNC axes position the workpiece and measuring system for precise measurement of all the required features fully automatically. Workpiece-specific fixing devices make it easier to load and unload workpieces. If required, the workpieces can be automatically identified and assigned to the quality data.

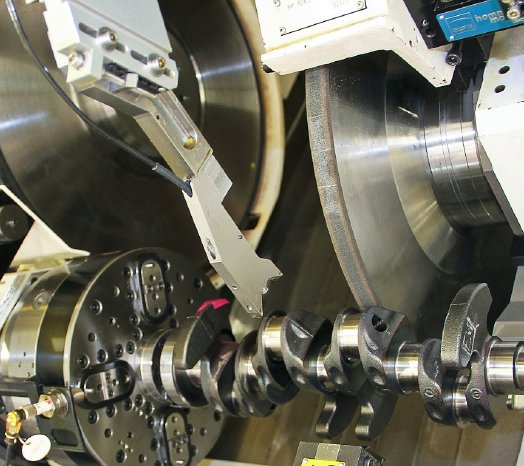

Hommel-Movomatic DF500: In-Process Measuring System for Crankshafts Now Including Waviness Measurement

The Hommel-Movomatic DF500 in-process measuring system has been developed specifically for use in modern pendulum grinding machines. During the grinding process, it checks the diameters of the main and pin bearings of crankshafts at full processing speed. The system features a particularly solid construction and therefore guarantees high measurement accuracy. Moreover, since the measuring device follows the movements of the crankshaft during the grinding process, the measurement is performed entirely without collisions.

Waviness is caused by a relative movement superimposed on the grinding disc and the workpiece. A newly developed and patented measuring procedure allows the waviness (chatter marks) on the main bearings and pin bearings of crankshafts to be measured in the machine tool using the DF500/DF700. This makes it possible to check for and detect waviness on bearing surfaces that could potentially impair operation even inside the machine tool.

There will be live demonstrations of all product innovations as well as other devices at Jenoptik’s exhibition stand: Visit us in hall 6, stand D26!