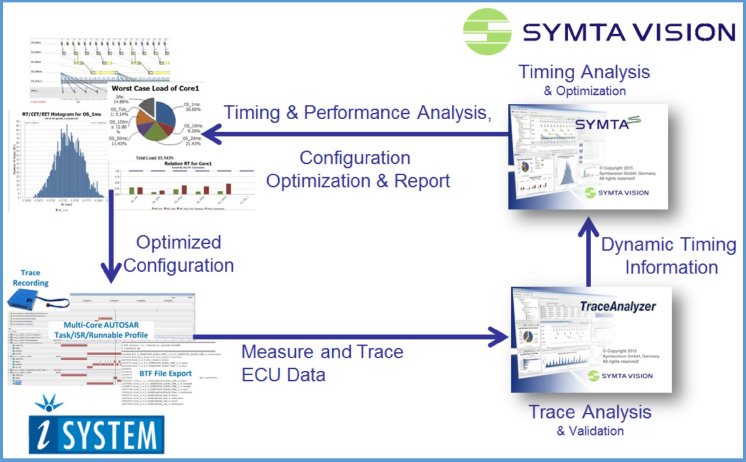

The collaboration delivers Symtavision tool support for Best Trace Format (BTF), the preferred file format for the iSYSTEM debug and trace tool, enabling trace data from single and multicore ECU’s to be imported into

TraceAnalyzer for visualization and analysis of timing traces and validation of ECU scheduling. Timing models generated from the traces can be processed further in SymTA/S to perform worst-case and statistical timing analyses, as well as to virtually change the scheduling and explore/optimize the overall software architecture. The optimized configuration can be passed back to the iSYSTEM debug and trace tool via an ECU configuration tool and uploaded to the target, completing the round-trip workflow.

Commenting on the improved tool integration and workflow, Dr. Kai Richter, CTO of Symtavision, said: “We have seen a lot of interest from companies wishing to take advantage of the integration of SymTA/S and TraceAnalyzer with iSYSTEM’s debug and trace tools in order to ensure the real-time safety and reliability of software. What was manual yesterday is now fully automated with the new features and functionality. The technical and commercial benefit is obvious: at the same time speeding up development and reducing development costs. ”

“Engineers can only develop safe, failure-free code with quality tools,” said Erol Simsek, CEO of iSYSTEM. “This is why we have further collaborated with Symtavision to make iSYSTEM’s real hardware trace recordings and Symtavision’s SymTA/S and TraceAnalyzer tools work together. This integration extends the capabilities of real-time tracing and offline timing analysis to a much higher level. It supports the embedded engineer to ensure that potential timing issues can be linked more quickly to the source of failure.”

About Symtavision

Symtavision® provides market-leading tools and associated consulting/engineering services for system-level timing design and timing verification – from early-phase estimation to final verification. Symtavision’s tools are used extensively in automotive electronics with support provided for all industry standards as well as a variety of other industry sectors including the aerospace, automation, multimedia, telecommunications and transportation markets. Symtavision is headquartered in Braunschweig (Germany) with subsidiary offices in Munich (Germany), Cologne (Germany) and Troy (Michigan, USA), and is supported by a global network of distributors. Symtavision is an AUTOSAR development member and also a founding member of the Real-Time Experts Alliance. For more information visit: http://www.symtavision.com.