New developments

1) HERBOLD Granulator with forced feeding (patent applied for)

A new feeding device for size-reduction machines will be presented:

The material to be size-reduced is no longer introduced into the grinding chamber by gravity but the rotor is evenly and horizontally fed by a screw conveyor. This way of feeding has the following advantages in comparison to a traditional constellation:

- Higher throughput (30 % to 50 % higher capacity performances if the granulator size remains the same in comparison to traditional granulators)

- Less energy consumption (30 % to 50 % less power input in comparison to standard granulators)

- The machine is not only available in a dry grinding execution but also in a wet execution for washing contaminated waste

- Even charges of the rotor (less fines and dust in the ground material)

- reduced sound emission (no material flyback)

A special advantage for the operator is that larger quantities can be stored in the feed hopper and treated automatically. A continuous manual feeding of the machine is no longer necessary. In addition, this type of feeding provides a high degree of security for the operator since a flyback of the material is totally impossible. The elimination of the large opening necessary for manual and/or conveyor feeding means a reduced sound emission during the size-reduction process. Possible ways of feeding are now forklift truck or dump body feeding.

Fig. 1: HERBOLD Granulator model SML 60/100

2) Herbold wash lines and components

The PET wash line procedure has been developed as an answer to the growing demand for a 'reusable recycling procedure for bottles'. The greatest advantages of this new PET recycling procedure are: no quality deterioration of the material, low energy consumption and at the same time an unchanged degree of cleanness.

Other characteristic features are:

PET is not thermally deteriorated Recrystallisation and polycondensation can be avoided Closed water circuit Lines available with throughput performances from 500 to 3000 kg/h

Herbold can also provide components for already existing wash lines:

wet granulators, friction washers, hydrocyclones, mechanical and thermal dryers.

Our plants for stretch film waste, our plastcompactors for densifying light materials, our shredders for size-reducing IBC containers without preliminary size-reduction and obviously our SMS and SML granulators, especially our workhorse SML 60/100, mainly chosen for barrels and bottles.

As an in-line or secondary granulator for injection moulding and blow moulding procedures, i.e. the size reduction of pre-forms or bottles, Herbold has developed the granulators of the compact C series with integrated sound insulation.

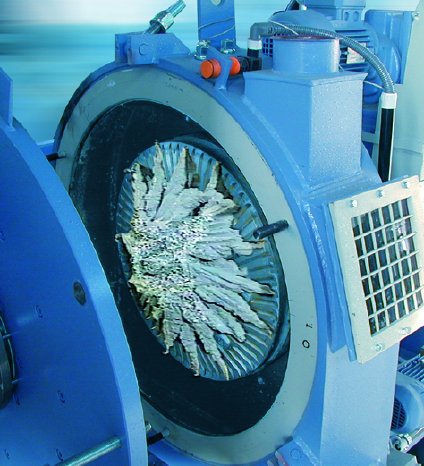

3) HGM - the so-called HOG shredder

HERBOLD Meckesheim GmbH has amplified their product range with a new series of slow-running granulators which are available in two sizes - HGM 60/100 and HGM 60/145.

Fig. 2: Herbold HGM shredder

type 60/145

The HOG shredder (HGM) is a single-rotor size-reduction machine uniting the advantages of a granulator (size-reduction by knife cutting, appropriate for relatively small screen holes) and those of a shredder (insensitive against foreign bodies, obtuse cutting angle, operation with a reduced rotation speed). It is used for size-reducing difficult materials, especially viscous ones or those containing many foreign bodies, where the service life of knives would be too short with traditional granulators, and normal shredders would not achieve the desired end product. The HOG shredder can be used in dry as well as in wet operation.

Typical fields of application are:

Pre-shredded used tyres

- Post-consumer bottles

- Metal-reinforced rubber or plastic parts

- Shredded waste from car recycling

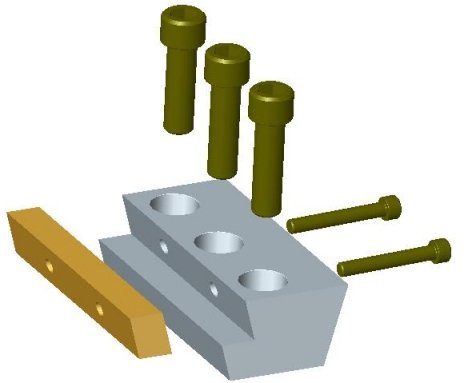

If the design is looked at, this HOG shredder is far more massive than normal granulators or shredders: the heavy over-dimensioned rotor is equipped with staggered knives (see Fig. 3); the extremely thick-walled grinding chamber is completely armoured inside with exchangeable anti-wear plates. The centrally hinged housing can be opened hydraulically and so ensures an easy access for maintenance and cleaning operations.

The knife insertion pouches of the rotor knives can optionally be equipped with tool-steel knives or with knife holders with interchangeable inserts (see Fig. 4). Depending on the use of the machine, the knives can repeatedly be resharpened (if normal material is processed) or, after having been turned once, will have to be replaced (if very fine material is processed). The stator knives are placed in adjustable knife holders; the knives are mounted in the knife holders outside the machine and adjusted with an adjustment jig.

4) The HERBOLD plastcompactor

The HERBOLD plastcompactor is a recycling machine for transforming waste with poor flowing properties into an agglomerate with high bulk density and excellent flowing properties.

Especially the kind of waste needing a particularly gentle treatment (such as PET and PA film, filaments and fibres) can be recycled in an extremely economic way and without any or only a minimal thermal deterioration.

The end product is an agglomerate with good flowing properties and high bulk density, free from fines and, if requested, even dyed. The granule size of the end product can vary according to the customer's requirements.

Many customers have already opted for the plastcompactor from HERBOLD MECKESHEIM GmbH (www.Herbold.com) since it best meets the high quality requirements. Due to the short residence time and the special just beginning sintering process ensuring that the material will not melt, voluminous waste with poor flowing properties can be turned into a 100 % reusable resource.

One example among many: treated PET bottles that have been turned into clean but badly flowing flat flakes after washing, separation and drying. With the help of the plastcompacting process, these flakes are not only turned into a material with excellent flowing properties, appropriate for a trouble-free gravimetrical dosing of film production lines. In one production step, the material is completely crystallized at the same time.

The HERBOLD plastcompactor HV 70 with a 250 kW drive is a workhorse obtaining a throughput of up to 1500 kg/h.

Fig.5: HV compacting disc Fig.6.: Agglomerate

HERBOLD has made every endeavour in order to promote the automatisation of the process and currently a fully automatised machine is available ensuring a trouble-free continuous operation without manual adjustment by monitoring the temperature in the compacting chamber.

Due to the low acquisition costs of the plastcompactor, its automatic operation and its low running costs, this machine is an interesting alternative to a reclaim extruder.