Disinfection with ultraviolet light

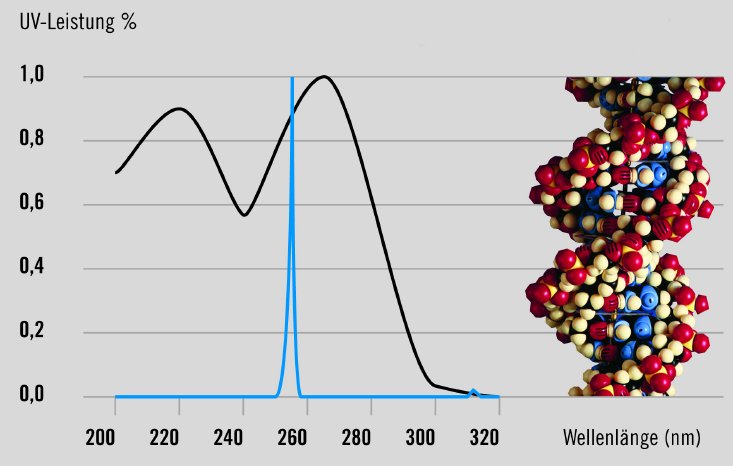

In general, the method used to remove bacteria from packaging materials is disinfection, not sterilisation: Ultraviolet light at wavelengths of 254 nanometer (nm) is more energy-rich than the terrestrial UV light of the sun. This especially short wave UV light destroys the DNA of all micro-organisms. When installed purposefully, viruses are disabled in seconds and micro-organisms such as bacteria, yeasts and fungi are killed in an environmentally friendly manner, without the addition of chemicals. For a whole series of micro-organisms, the lethal dose of UV radiation is known and this is the dose after which the cells can no longer maintain their metabolism and can also no longer multiply. Because of the cell wall structure, the lethal dose for different pathogens is distinctly high. Consequently, bacteria such as salmonella and coli bacteria, which have a comparatively thin cell wall and can thus only slightly block the UV radiation, are extremely vulnerable and are very quickly destroyed. On the other hand, mould spores protect themselves against UV radiation with a thick cell wall, which can even be pigmented. To kill these, a UV dose which is 10 to 100 times higher than that required for bacteria is needed.

The required lethal UV dose is an important parameter in the design and selection of suitable UV radiation sources. Machine speed, geometry and shape of the packaging (for example cup or sealing foil) are further criteria in the design of an effective disinfection process.

The necessary UV dose is calculated by multiplying the irradiation power (intensity) of the UV lamp by the length of time that irradiation takes place. The intensity of the radiation is also dependent on the distance between the UV cassette and the packaging. The UV intensity of a lamp decreases with the increase in operating hours. At the end of the lamp operating life there must still be sufficient high UV intensity to ensure a suitable disinfection power and the necessary lethal dose in the given radiation time.

Experience with Yoghurt filling for example has shown that pots of a depth of 150 millimeters (mm) can be effectively disinfected within four seconds and sealing foils in two seconds at the same intensity.

UV disinfection is used especially for the packaging of acidic fresh milk products, such as yoghurt and kefir, which are kept in the cool chain, in order to improve shelf life. This means that the dairy has significantly fewer returns of spoiled product, saving time, effort and cost of disposal.

Up to 99.9 percent germs removed - Fraunhofer proofed

Even more intensively and reliably, the Heraeus Premium UV modules reduce the number of germs on the surface. The latest powerful modules have been developed especially for UV disinfection in the food industry. They remove up to 99.9 percent of germs. This is proofed by the report of the Fraunhofer-Institute for Pocess Engineering and Packaging, Freising, Germany. According to a method of the association VDMA, Frauhofer has tested the efficiency of the decontamination by using Premium UV Modules against certain micro-organisms (conidiospores of Aspergillus niger, endospores of Bacillus subtilis). During this count reduction test three respectively five log levels have been achieved within a distance of 20 mm.

The use of a novel lamps technology enables high intensities and a substantially longer service life. The use of just one UV cassette reduces the expenditure for servicing and associated costs. The short exposure times also contribute to reducing operating costs. Depending on the material, between two and four seconds are sufficient for the disinfection process.

The UV lamp is virtually the only consumable necessary. It has a service life of up to 12,000 operating hours which is equal to two years of actual use at 24 hours of operation per day. During that time, the Premium UV module can sterilise about 173 million cups on a machine with eight lanes. This means an investment of just 0.03 Euro cents per cup, a lot less than one Euro cent.

Easy handling - high safety

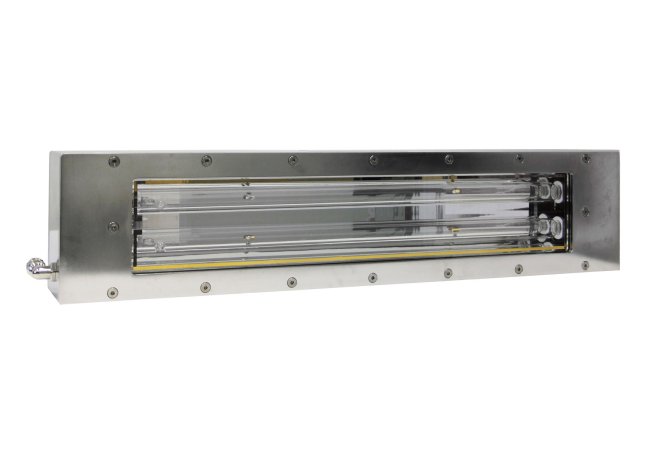

In addition to the economic benefits, the Premium UV modules feature easy installation and operation. The modules can simply be installed or retrofitted to existing filling and sealing plants. Due to the integration into the respective HACCP concept, the quartz glass plate, the temperature and the emitter function can be monitored automatically. The quartz glass covers of the UV cassettes are provided with a breakage detector patented by Heraeus and thus part of the HACCP concept. If a quartz glass plate breaks, the detector sends a signal to stop the filling plant immediately. The type of protection of the Premium UV module is IP67, so it can also be used without restriction in wet environments of a CIP-machine (CIP = Cleaning In Place). Translucent plastic doors, e.g. made of Makrolon, are sufficient to provide protection against the radiation.

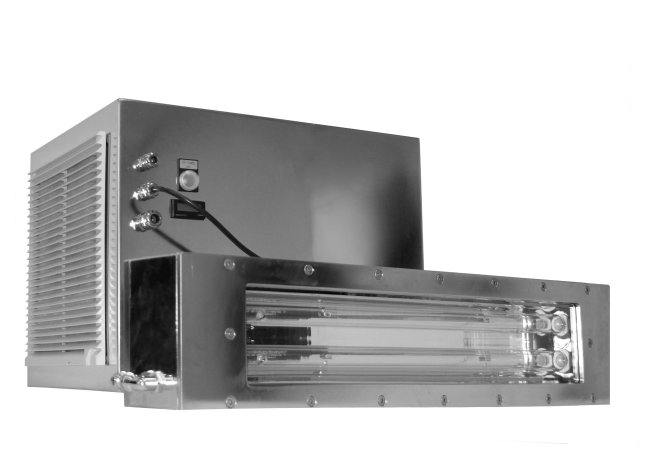

Electronic control unit and ventilation are combined in a new media box to make retrofitting even more easy and reduce the space requirement. Based on the modular design principle, one to three UV cassettes can be operated with one media box. Expensive water cooling is not used as the Premium UV modules are cooled with air. The ventilation provided by one media box is sufficient to cool up to three UV cassettes. The media box is stainless steel design and EMC-protected (electromagnetic compatibility) and can be operated anywhere in the world at supply voltage frequencies of 50/60 Hz. The box has two 180 - 264 Volt connection sockets. Premium UV modules are equipped with an operating hours counter and an on/off lamp signal to make the entire monitoring process easier.

As an option, the Premium UV module may be equipped with a patented quick-start solution. This will reduce the warm-up time from about five minutes to 30 seconds, so the filling process can start more rapidly.

High-intensity and nevertheless cold

Due to their slim shape, Premium UV modules are used in particular to sterilise packaging materials in in-line filling machines with four to twelfe rows of cups. As a standard, the new Premium UV modules are available in three sizes but they may also be adjusted especially to the machine enviroment. Although the UV cassettes generate a high irradiance, the UV light is cold. Therefore, the packaging material is not heated. This makes the disinfection method perfectly suited for the treatment of heat-sensitive materials such as plastic cups and sealing foils.

Taking account of various dimensioning criteria and with a suffiently high irradiance, UV disinfection is used as a simple, fast and reliable method in continuous operation in filling plants. However, outside the food production industry as well, e.g. to disinfect packaging materials in the pharmaceutical and cosmetics industry, the method of surface disinfection with UV light makes an important contribution wherever bacteria and viruses need to be inactivated in an environmentally-friendly manner.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China and Australia, is one of the technology and market leaders in the production of specialty light sources. In 2010, Heraeus Noblelight had an annual turnover of 98.9 Million € and employed 689 people worldwide. The organisation develops, manufactures and markets infrared and ultraviolet emitters for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical laboratories.