THE ADAMS and THE BENJAMIN , the filling systems for packing powder-type products into air-tight PE bags made from a tubular film roll, are increasingly taking the market. The advantages that these Haver & Boecker designed HAP (Haver Adams Process ) systems, which use the Form-Fill-Seal principle, have to offer are the long-sought customer wishes of more product protection, greater transport stability and longer shelf lives. The PE bags in which premium quality building chemicals, dry mortar and cement are packed into also provide for a perfect appearance. Compact sizes and high flexibility are the distinguishing features of these machines. Depending on the production outputs and the level of compaction to be reached by the fine-powder products, THE BENJAMIN may be equipped with 1 to 4 filling modules, and THE ADAMS with 8 or 10 spouts.

THE CYRUS, based on THE ADAMS and THE BENJAMIN , is the newest innovative FFS model of the Haver & Boecker product line and will be displayed to the public for the first at the INTERPACK. THE CYRUS is a new development for powder-type, loose materials with particle sizes ranging from 20 to 300 (e.g. products of the chemicals and food sectors) and for coarse products with dust content (e. g. sugar, salt and flakes), and thus can be the key to filling success. Frequent product changeovers with required cleaning are no problem for the HAVER-CYRUS. THE CYRUS is designed for bag sizes ranging form 6 dm3 to 50 dm3 and weights between 5 and 50 kg. Economy, flexibility and cleanliness are the distinguishing hallmarks of this system. It has a completely enclosed product path (dust-tight filling spouts) and speeds of up to 1500 bags/hour. THE CYRUS opens up for its customers a whole new range of possibilities, which up to now have not been possible with the conventional FFS systems, or only for valve bags.

Compactness, user friendliness and reliability are the features that characterise the proven HAVER-INTEGRA system for valve bags. This fully automatic compact system includes an automatic bag applicator, a filling system, valve sealing unit, control unit, operator s terminal and a discharge belt - all optimally placed inside a dust-free housing. This system is delivered ready for production. It uses the Plug+Pack concept and can be set up and put into operation at the customer s location in little time. It fills all bulk materials with speeds of up to 700 bags/hr. with 1, 2 or 3 filling spouts.

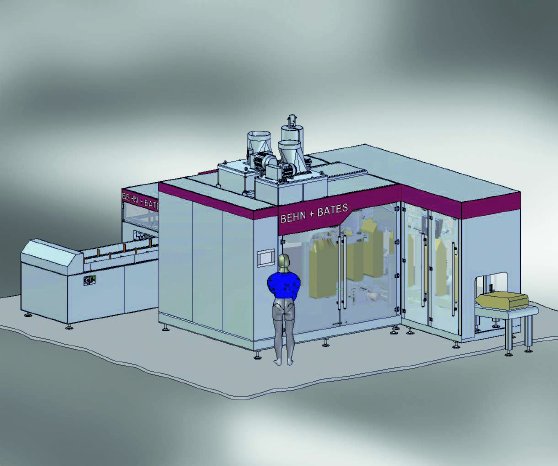

HAVER subsidiary Behn + Bates, which this year can be proud of its 75th anniversary as an expert in packing food and feed products, is now offering its customers two new products. One is the ORBIS open-bag system, and the other is the proven turbine packing system with improved design and integrated metal detector.

The ORBIS is an extended development of the TOPLINE system introduced at the 2005 INTERPACK. This new rotating filling system for open pre-manufactured bags assures an efficient and hygienic product filling and a high machine speed of up to 600 bags per hour. It s especially suitable for packing flour, baking powders, powdered sugar or powdered milk. It can work with all conventional bag types, e. g. side gusset bags or bags made of paper, PE, woven PP or material combinations, and may be equipped with 3, 4 or 5 filling spouts that work separately from each other. Now it is possible to let single filling steps to take place parallel to each other, thus yielding short cycle times, high outputs and excellent weight accuracies. By selecting the right bag material and an air-tight closure, even longer product shelf-lives can be attained. The new filling and weighing system distinguishes itself through GMP and hygiene-conforming design. Together with a new type of dosing system, an innovative, customer-friendly and low-maintenance filling system that takes the strict standards for food packing fully into account has been created.

The proven Behn + Bates turbine packer, which is used for filling cocoa powder, baking flour or starch products into paper valve bags, was further developed to improve quality control. A filling channel with integrated metal detector detects if there s metal in the product. Other new features include simplified access for cleaning and maintenance work.

Feige Filling, also a subsidiary of the HAVER GROUP, will present its technical expertise in filling liquid and pasty products. Such filling can be done using the fully automatic Model 34 Plug&Fill system for buckets and canisters. The system uses the Feige-developed and patented product flow control system, which in combination with the product pump reduces filling times to a minimum.

Feige Filling is also presenting the Model 33 drum filling machine for filling steel and plastic drums. It is equipped with Feige-quality components and an automatic shutting station, and can be installed and put into operation with minimal effort.

With the catchwords Plug&Fill and ATEX-conforming, Feige Filling Model 16 swivel-type pallet filling station fulfils the special needs of the market. It s available in either mobile or stationary design and is used for the automated and calibrated filling of drums and containers, as well as IBCs that are placed on pallets.

As a leading global manufacturer of filling systems for loose, bulk materials and liquid products, Haver & Boecker in a joint development with Feige Filling have succeeded for the first time in developing and building a fully automatic system for filling pasty products into plastic bags- the LIFFS. This development demonstrates how the HAVER GROUP and its subsidiaries can bundle competences and expertise to generate new technologies for the benefit of its customers.