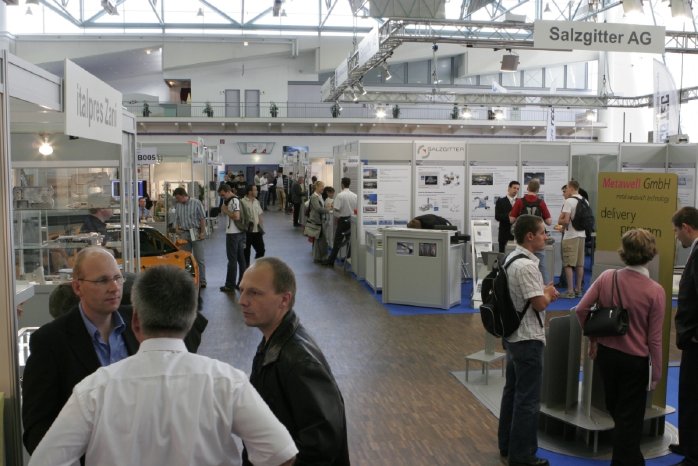

Trade fair premieres are always exciting. The key questions are: Can the organiser manage to get a fair that meets visitors' requirements off the ground? And is there enough interest to make it worth the effort for exhibitors? The answer to both these questions was "yes" at the inaugural euroLITE, European specialist trade fair for lightweight design. The trade fair, which was organised by H & K Messe GmbH, together with the Salzburg Exhibition Centre, covered the entire range of services and products in lightweight design – from construction and simulation tools, through materials, prototypes, deformation technology and joining techniques, to the serial production and testing of lightweight components. "We were particularly pleased that more than half of the 128 exhibitors used euroLITE to present new technology", commented Claus Hähnel, Managing Director of H& K Messe. This enabled the specialist lightweight design fair to offer the 1,542 professional visitors from eight countries a unique information and procurement platform in Europe. As expected, the majority of visitors came from the automotive area, followed by mechanical engineering, railway vehicle and commercial vehicle construction, aerospace and other industries, in which it is important to reduce weight when developing new products.

In-depth discussions with experts and valuable new contacts

Not only the quantity of visitors was impressive, but also the fact that they were so well qualified, and included so many decision-makers. 91 percent are involved in making procurement decisions within their businesses. The quality of contacts and discussions, which lead to concrete enquiries, was also very high. "We were surprised by the quality of the visitors and the number of valuable contacts we were able to make during euroLITE. We are particularly pleased to have received a large quotation request as a direct result of these contacts“, reports Andreas C. Schmitz, Key Account Manager at Sapa Aluminium Profile GmbH. Birgit Mayer, Managing Director at WF Wabenfabrik GmbH, shares a similar opinion: "For us, it was definitely worth participating in euroLITE. For example, our stand was visited by well-known automobile manufacturers like Porsche, DaimlerChrysler, Honda and Mazda, and we were also able to establish some very interesting contacts with company representatives from other industries. For this reason, we will certainly exhibit again at euroLITE". Aldert Verheus, from Dutch company Leightweight Structures BV, is also certain that he will be back at euroLITE 2008: "For me, the trade fair was a great success. I was able to establish contacts with companies like AUDI, MAN, and Siemens". Robert Wurzer, Sales Manager at Voestalpine Krems GmbH, also gave a positive evaluation: "euroLITE is a small, but excellent event. We were able to improve existing business relationships here, and also to make new contacts". Martin Launhard, Sales Manager at Schuler Hydroforming GmbH & Co. KG, established that the inaugural lightweight design fair was already able to keep up with other trade fairs: "I was recently at EuroBlech, but was able to conduct more interesting discussions within two hours at euroLITE than I was in an entire day there. This shows me that we made the right decision in coming here. euroLITE is already a bit of a highlight for us". Ralf G. Franke, regional head of sales at Gerhardi AluTechnik GmbH & Co. KG, visited euroLITE as a scout to sound out whether or not it was worth his company taking part in the fair. He came to the following conclusion: "My visit and discussions with exhibitors gave me the impression that this is a very interesting fair, and is most certainly worth a try". Visitors were also happy with the range of exhibitors. Frank Preller, who works in development/lightweight design at B&W Fahrzeugentwicklung GmbH: "I travelled to Salzburg because the fair was not specifically for bodywork or vehicle construction, but lightweight design in general. This allows you to see how lightweight design problems are solved in other areas. The selection of exhibitors is very good, and you really had time to hold in-depth discussions with many different companies in one place. This is not the case at other trade fairs. I'm therefore very glad that I allowed myself three days for my visit to the fair".

Trends in lightweight design

It goes without saying that euroLITE also dealt with trends in lightweight design. An important topic here was carbon fibre reinforced plastics. This deals primarily with the industrialisation of manufacturing. "Manufacturing with carbon fibre reinforced plastic is still largely manual. For future markets, we must think in different dimensions and continue to develop or completely redevelop our manufacturing technology", explains Professor Dr. Ing. Wilm Unckenbold, who teaches in the specialist area of fibre-reinforced composites at the Private University of Applied Sciences in Göttingen and is one of the heads of the CFK-Valley Stade e.V. competence network. Approaches for a higher degree of automation do exist. These include, for example, the Auto-RTM procedure, which is already up and running in a test facility. From the cutting of semi-finished fibre products, through insertion into the tools, to the injection of resin, all steps are fully automatic. New tape-laying systems form another approach. These machines can also lay semi-finished fibre products on curved tools. "The drilling and milling of fibre composites still causes a high degree of abrasion on the tools. Work is underway to develop more efficient tools. Other topics include material recycling and component testing. A very important point is also the training of skilled workers and engineers. This is because there is currently a deficit in fibre composite specialists", said Professor Unckenbold, naming some of the problems to be solved in the future. Circular profiles and shafts are already being mass-produced from carbon fibre reinforced plastic and glass fibre reinforced plastic. They are used in inspection cameras, car aerials and seat posts, and also help to increase productivity in the manufacturing of silicon plates or nappies, as well as in treatment systems. For Oliver Kipf, Managing Director of CG TEC, the potential use of these lightweight parts is far from being exhausted. "Mechanical engineering will be very important area of usage for us in the future. Carbon shafts mean plants can be run faster, for example for filling drinks, and thus means that the user can see the advantages", says Kipf. A further trend in lightweight design is the continued investigation of composites whose properties can be tailored to the respective applications. "In the area of composites, it is important that a numerical simulation of products can be executed. Time-consuming equations are needed in order to be able to judge and predict the mechanical behaviour of these new materials", explains Professor Dr. Ing. Otto Huber, from the University of Applied Sciences in Landshut. In the opinion of the lightweight design expert, advances must also be made in joining techniques. "It is also important to solve the problem of contact corrosion, and to align the mechanical properties of the joining technology used (for example, gluing) to the different materials", Professor Huber continues.

The specialist lectures within the lightweight design forum, which were organised by the Landshut Light Construction Cluster, were also in great demand. Depending on the subject, between 30 and 120 visitors used the opportunity to find out about current solutions, new developments and trends in the areas of construction, materials, and manufacturing technology for lightweight design.

euroLITE not only achieved the goals of the organisers and exhibitors, it exceeded them. This confirms that the trade fair concept of the European specialist trade fair for lightweight design filled a "gap in the market". "By the end of this year's trade fair, over 20 percent of the exhibitors had already reserved a stand for the next lightweight design fair. This is an excellent indication that euroLITE 2008 can expect to be even bigger", reports Wieland Kniffka, Managing Director at H & K Messe. The second euroLITE European specialist trade fair for lightweight design will be held from June 24 to June 26, 2008, in Salzburg.

We thank you for sending us a copy of your publication.

Contact for editorial offices and for requesting photo materials:

H & K Messe GmbH & Co. KG

Wieland Kniffka

Kaiserstraße 142-144

D-76133 Karlsruhe, Germany

Tel: +49 (0)721 570 444-00

Fax: +49 (0)721 570 444-22

w.kniffka@hundkmesse.de

www.hundkmesse.de

SCHULZ. PRESSE. TEXT.

Doris Schulz

Martin-Luther-Straße 39

D-70825 Korntal, Germany

Tel: +49 (0)711 854 085

Fax: +49 (0)711 815 895

doris.schulz@pressetextschulz.de

Member of Absolut… Network