GearEngineer is a software application for the calculation of the accurate 3-D gear tooth form. The tooth form can be used to manufacture gears with free form milling on universal multi-axis machining centers. The accurate 3-D gear tooth form is calculated according to a mathematical simulation of the manufacturing process. 3-D geometries are identical to the gear tooth form of real, conventionally manufactured cylindrical and bevel gears. An involute tooth profile for cylindrical gears and an octoidal tooth profile for bevel gears including the real root contour will be obtained. This helps to ensure that the tooth root strength is achieved.

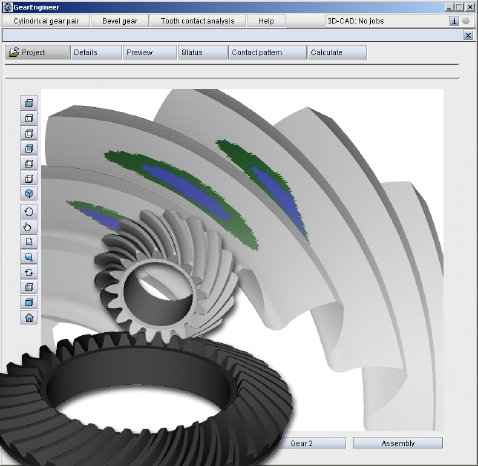

GearEngineer contains a tooth contact analysis (TCA) to calculate and optimize the contact pattern of gears before the manufacturing process starts. The contact pattern gives some insight into the required geometry. Especially for bevel gears, it plays an important role for improving smoothness and quietness of operation. The gears are automatically checked for collisions or interferences. Deviations and displacements from the ideal mounting position can be also defined. The simulation process can be compared to present inspection methods where the contact pattern is obtained when the gear set is run under light load in a rolling test machine. The tooth contact pattern is visually displayed on the gear flanks. The tooth contact areas can then be evaluated for acceptibility. If size and location of the contact pattern do not comply with technical requirements, the tooth contact pattern can be easily modified, even before the first chip falls. Many customers have been using the tooth contact analysis for the past several months. According to these customers, the tooth contact analysis worked very well and was almost 100 percent identical to real tooth contact patterns. Many spiral bevel gear sets, manufactured by using the free form milling method, were investigated. Adjustments and modifications of pinion and gear, which are usual when using traditional manufacturing processes, are not required any longer.

For more information, please visit GWJ during AMB Stuttgart in Hall 4 / Stand A15 or contact GWJ by phone +49 (0) 531 / 129 399-0 or email info@gwj.de as well as www.GearEngineer.eu.