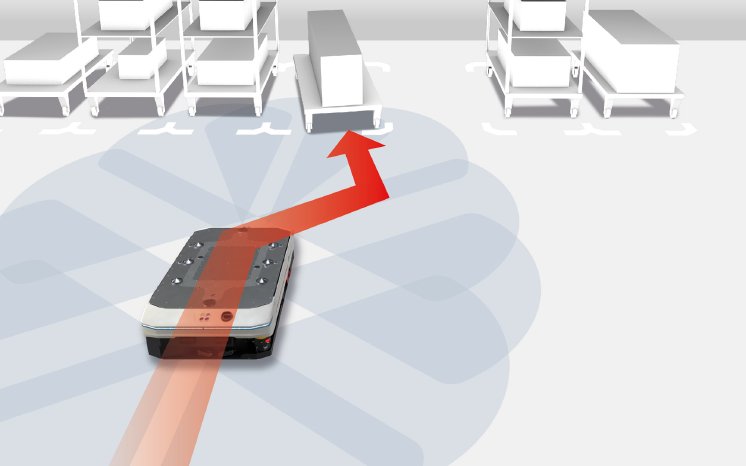

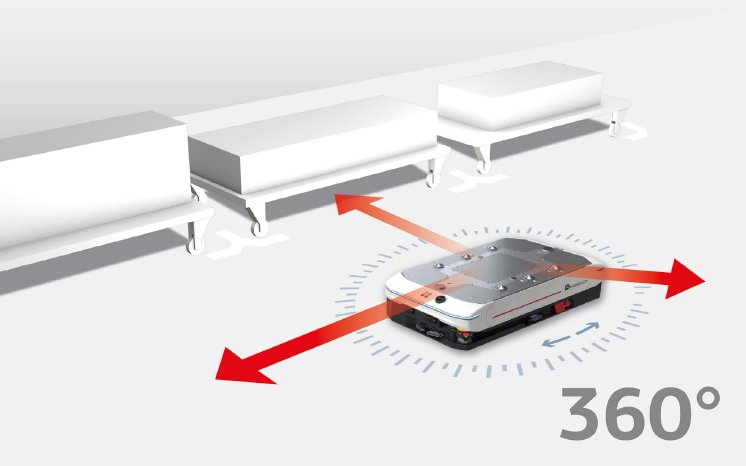

More autonomous, quicker, and smarter – with the new OL1200S, Grenzebach presents the next generation of automated guided vehicles for long goods carriers and payloads of up to 1,200 kg. It is omnidirectionally drivable and is equipped with smart sensors. This allows the OL1200S to transport large components in the smallest of spaces.

Specialist for long Load Carriers

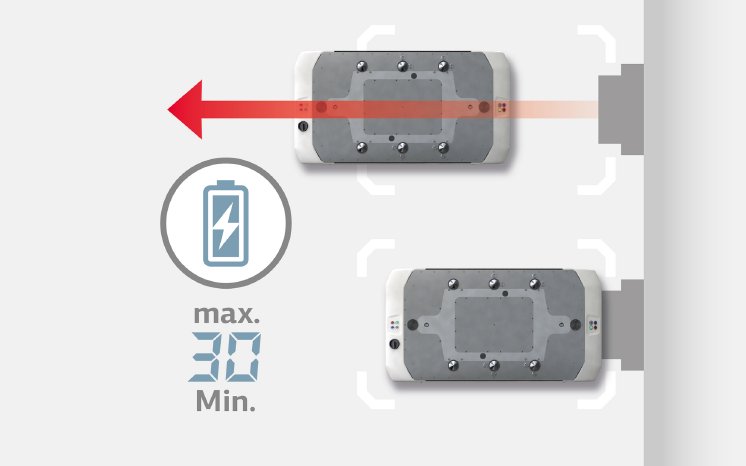

The high maneuverability of the OL1200S especially allows for space-saving cross-docking of long goods or load carriers. Further transport in direction of the shorter edge does not require any rotation of the AGV. An autonomous load carrier detection identifies inaccurately placed loads carriers and allows the OL1200S to pick them up autonomously. No additional sensor technology or adaptions of the loads carriers are needed. Stations are no longer necessary. In early adopter customer projects, the space required for delivery stations could be reduced by 75% as opposed to a classic tugger train or an AGV-based solution with differential drive. Additionally, users benefit from lower investment costs and shorter time for implementation. Existing solutions can be adapted easier and quicker than has been the case so far. This is why the OL1200S is particularly beneficial for production environments that need a high degree of flexibility.

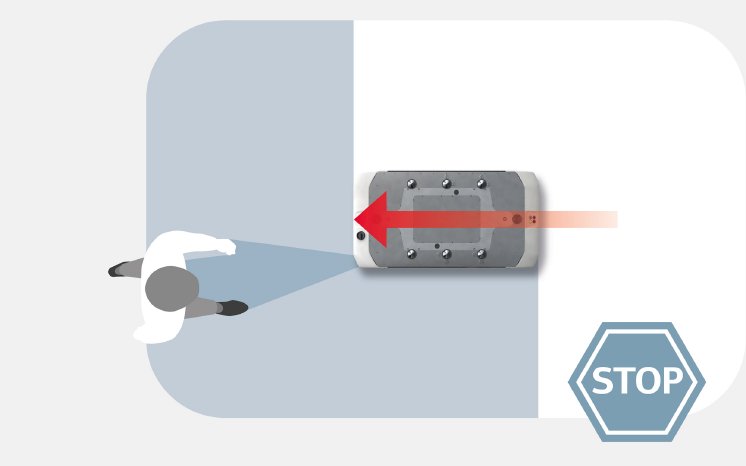

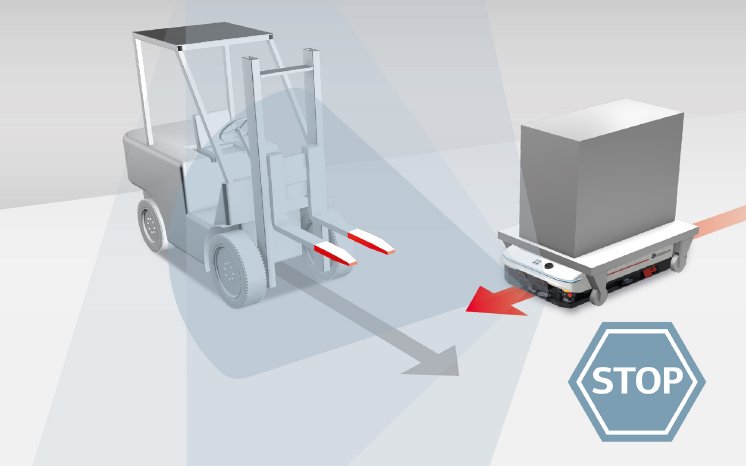

All-round safe

Equipped with both Lidar and 3D vision systems, the AGV also sets new standards for personnel and transportation safety. This enables its simultaneous use in areas with pedestrian traffic and prevents transportation damage caused by collisions with obstacles in the operating area, such as protruding components, partially open roller doors, or forklift tines. The AGV can reach speeds of up to 6 km/h and handle inclines of up to 5%.

Holistic Solution for automated Goods Transport

The new vehicle can be used along with the trusted L1200S with conventional drive in one system. Combining the strengths of both vehicles results in a highly optimized automated goods transport in manufacturing and logistics. Both the Grenzebach Fleet Manager and the new OL1200S are VDA 5050-compatible. This makes a combination with AGVs from third-party manufacturers in one system a nonissue.

OL1200S: Award-winning technology package

This also convinced the independent jury of the LogiMAT “Best Product” award. Each year, the prize is given to products, which contribute significantly towards rationalization, cost-savings and increasing productivity in in-company logistics, according to LogiMAT. It has become one of the most coveted in the intralogistics sector and products can be submitted in three categories. The OL1200S is the 2021 winner in the category order picking, conveying, lifting, storage technology.