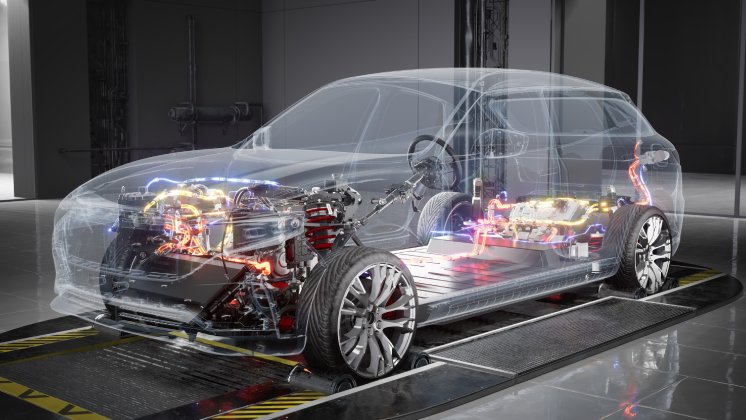

Farasis Energy has been innovating in the battery industry for more than twenty years, working on solutions such as the use of cell-to-pack design. Therefore, the company was actively involved in the PEAk-Bat project, a cooperation between several companies that is financed by the federal government. In the cell-to-pack design, the basic three-part structure is replaced by a two-part structure. Cells are integrated directly into the pack housing instead of modules, which in turn are integrated into packs. This approach increases the gravimetric and volumetric energy density of batteries and increases efficiency by up to 20 percent. The number of components required is thus significantly reduced and contributes to a reduction in costs.

At AABC, the company will be presenting a selection of its comprehensive portfolio of solutions – from battery cells to modules and packs – with customization available.

The high-performance lithium-ion battery technology is characterized by long range and fast-charging capability: With an energy density of 330 Wh/kg, a range of approximately 1,000 kilometers can be achieved. Customers who value fast charging will benefit from a battery with an adapted cell design. This allows the battery to be charged from 10 to 80 percent in just 15 minutes in fast-charging mode.

An outlook into the future of battery technology

Aslan Göger, Director Business Development, will share his expertise in a presentation entitled "Trends and Developments in Battery Performance" at 3:10 p.m. on May 16th, which is part of the xEV Battery Technology track. In the subsequent panel discussion, the topics relating to battery developments for passenger cars will be explored in greater depth.

"Farasis Energy combines over two decades of expertise with a pioneering spirit. With our comprehensive product portfolio from market-leading battery cells to modules and packs, complemented by our Engineering Services, we offer solutions for the requirements of different industries and the electrification of their vehicles”, says Göger.