Solder paste printing, mounting, and soldering are quickly adapted to a new design. For example, a new solder paste stencil can usually be produced within one day. The mounting machines do not create a bottleneck either thanks to their distinct set-up stations. Compared to these processes at the beginning of the production line, in-circuit testing involves considerably more work for two reasons: the possible need to make mechanical changes to the fixture and updates to the test program. One idea would be to switch to flying probe contacting, which can be tested without an fixture, but it cannot close to the cycle times offered by an in-circuit tester.

Effective planning of set-up times

In production planning, knowing how long this ICT changeover process will actually take is crucial. For test engineers to estimate the extent of the modifications on the assembly and their impact on the fixture and the test program, they need detailed information. When the test experts ask what has changed, they are told "only a little" or "nothing of importance," statements which, at best, only allow a rough estimate based largely on past experience.

In most cases, the assembly comes with a lot of paperwork. These change reports fill entire folders and it is time-consuming to filter out the relevant information for the test in addition to reports on screws, cables, and plates.

Data management is everything!

The test engineer finds the relevant information in the BOMs, schematics, and CAD data. A suitable software solution would be able to compare the data at different development stages and provide meaningful evaluations. C-LINK is a CAD/CAM software from Digitaltest which produces all of the necessary data for the assembly and testing of printed circuit boards.

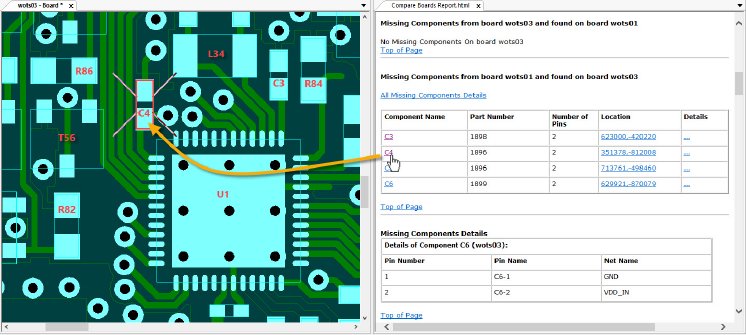

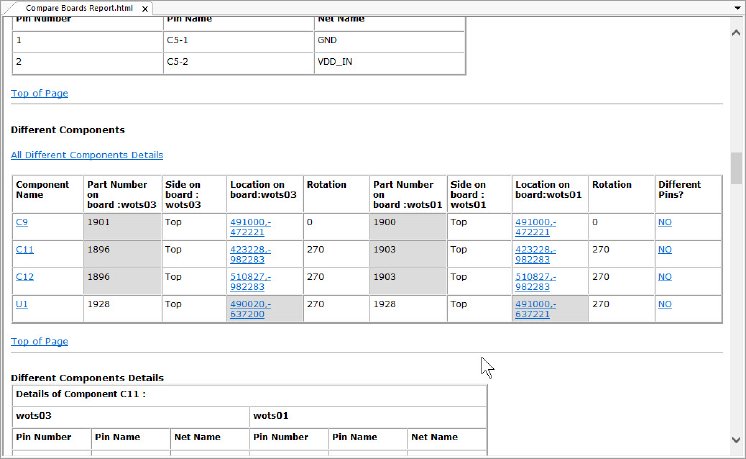

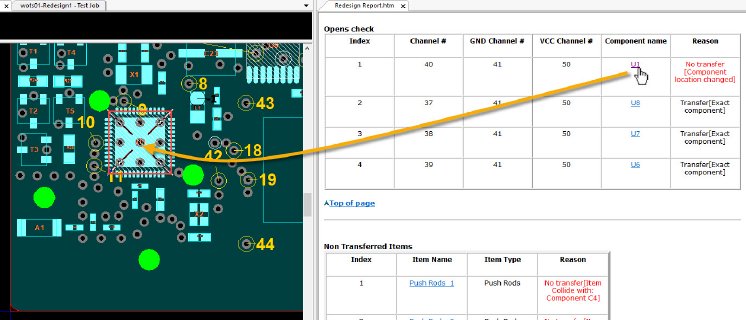

All revisions are entered into the CAD data. If this data is imported into C-LINK, the software recognizes the differences in the layout status. The “Compare Boards” function then delivers a detailed report within a few moments. The differences are listed in clear tabular form and displayed in the layout. Differences in the component values and in the net list are found as well as missing and added components. Thanks to this quickly available overview, the test engineer can make a realistic statement about necessary changes in the test program.

What influences the test program?

The report created with the Compare Boards function in C-LINK allows quick navigation via hyperlinks. This can be used to create a list of what needs to change in the test program: If the assembly has changed, measured values must be adjusted in the test program. If components have been added, they must be recorded. If, on the other hand, components have been removed, the test steps are commented out or deleted. If components are connected to other networks on the new module version, they will be tested via other test channels in the future. The redesign tool helps with the implementation.

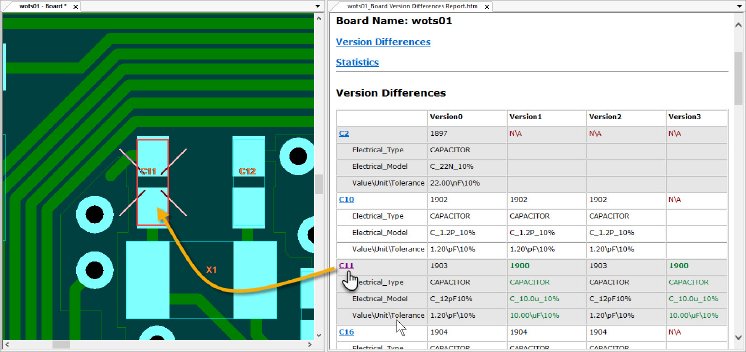

C-LINK also helps with assembly variants. Using the "Version Differences" function, a report clearly displays the differences in the placement. The component properties to be compared can be set manually. The comparison is stored as an HTML file in the board directory and the components are linked with hyperlinks to the graphical display. If the test program development is advanced or already finished, the automatic program generator (APG) in the system software CITE can extend the existing test program by one or more new variants in an update mode.

Continue to use existing fixtures

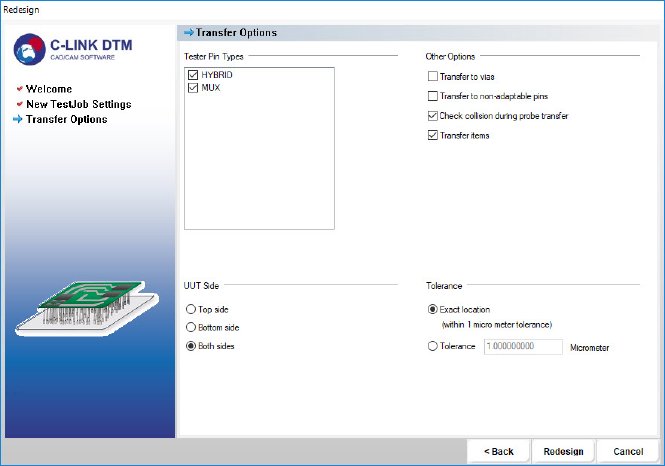

In addition to the test program, the design modifications also have decisive consequences for the existing test fixture. In addition to needle positions, channel numbers, diameter, and head type, the fixture design in C-LINK can also include all mechanical components (e.g. catch pins, hold-down pins, spacers, transfer pins, OpensCheck plates, etc.). The software can, for example, produce a table listing which tester pins can no longer be used because the test pad has been moved in CAD. This is a standard function in many CAD/CAM solutions, but C-LINK offers more here. All of the mechanical components of the old fixture are checked and, if possible, transferred to the automatically generated TestJob. If, for example, a component is moved so that a collision with a hold-down occurs, this is reported. This report can help the CAD developer to make the assembly testable with the existing fixture. This not only saves time, but also money, since the fixture no longer needs to be converted. In addition, several revisions can be tested with a single fixture, meaning less storage and conversion costs.

If, due to different CAD systems or release versions, there are differences in zero point, factors, or units, for example, not only can C-LINK handle these, but even support tolerances. For example, if a test pad is shifted by a few hundredths of a millimeter, whether by the developer on the layout system or by rounding the export/import interfaces, the tester pin is transferred accordingly.

Implement changes quickly

If the modifications are so extensive that converting the fixture is necessary despite the redesign function, C-LINK generates all the necessary data. If the original fixture was not designed with C-LINK, it is often sufficient to import a wiring list to emulate the fixture in C-LINK. All redesign tools are then available.

Fast steps to the result

The new CAD data is compared with the released BOM via a freely configurable BOM import module. In just a few processing steps, probes are placed on the nets which are no longer or not yet contacted, taking into account the existing adaptation. The drilling data output only writes the newly added tester pins to the CNC files. These delta files contain all of the necessary information to re-drill and wire the existing fixture. If the changes are too extensive and a new fixture is necessary, C-LINK will, of course, provide the complete drilling and wiring data.

New board versions: no problem with Compare Boards

The Compare Boards function offers valuable services that quickly indicate the extent of required changes to the test program. This report also serves as a working document for incorporating the modifications into the test program. C-LINK increases the performance of in-circuit test systems by enabling rapid adaptation of test processes to new module versions. More information at www.digitaltest.com

Author: Olaf Rohrbacher

Product manager for CAD/CAM software and with Digitaltest for over 20 years.