Visit Digitaltest at IPC APEX EXPO in San Diego, California, booth 3533 from January 26-31, 2019.

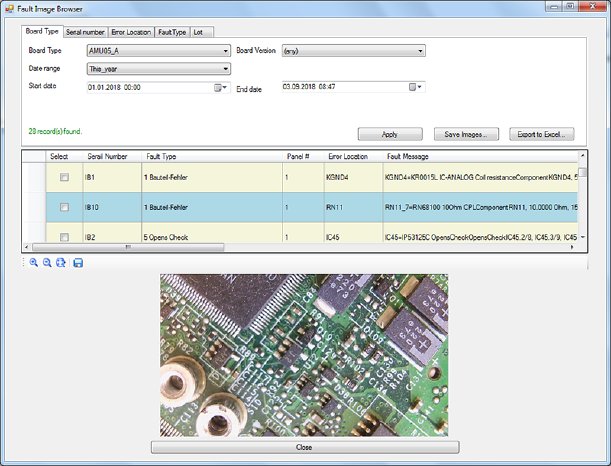

New app: Fault images simplify repair

A picture says more than 1,000 words. This was the phrase that the developers from the test system manufacturer Digitaltest had in mind when they programmed the Fault Image Browser. Here, a camera connected via the PC takes pictures of found failures. Photos of assembly faults, defective components or successful repairs, for example, can be taken, saved and evaluated. This app is part of the Paperless Repair Software QMAN from Digitaltest. It helps all common test systems to repair faster and to observe and evaluate the manufacturing process.

This QMAN function can help customers to better visualize recognized defects, especially in electronic manufacturing services (EMS). Of course, a fault image also supports repairs and makes it possible to record the successful repair photographically.

Parallel test reduces test time significantly

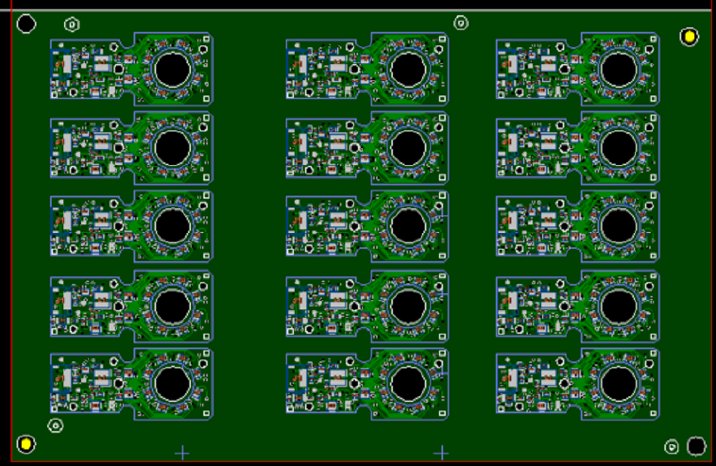

Panelization has become indispensable in electronics manufacturing – the advantages are obvious: even miniature PCBs can be tested and higher quantities can be tested in a shorter time with less use of resources. If, for example, the test system is to test an eight-fold panel instead of a single unit, this requires more time within the production line - a jam could occur. Here, a parallel test can reduce the test time to such an extent that the user test fits into the cycle time of the line. With the parallel technology of Digitaltest, the Lambda edition, the single boards are tested simultaneously on the multiple panel and thus the tests are carried out in the fastest way. This works by performing an in-circuit test, or functional test on two or more independent test heads, thereby reducing the test, time by the corresponding factor.

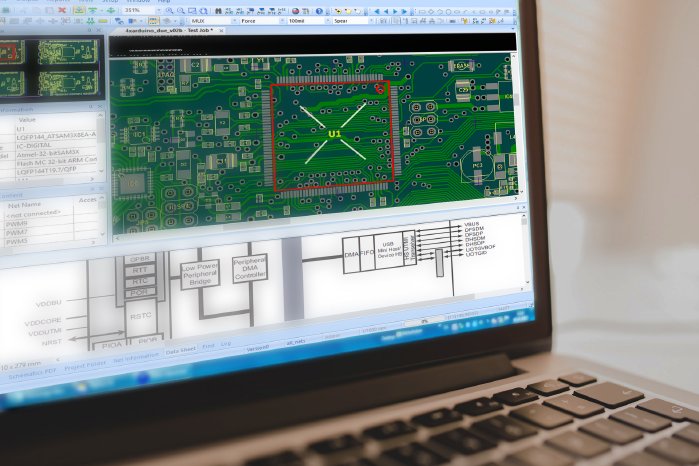

Advanced CAD translation solutions: C-LINK DTM

C-LINK DTM takes all major CAD systems and automates the translation of design data to any test in-spection system. By linking design for testing (DFT) to production, profitability and product quality are increased, test costs reduced, and testing and product introduction times shortened.

Be multifunctional: the vacuum test system Sigma MTS 300

Visitors to the Digitaltest booth can get a live impression of one of the fastest in-circuit testers on the market. Our Sigma MTS 300 has been designed for high throughput capability and with up to 1000 measurements per second. The test system can check printed circuit boards with up to 3,456 analog, 1,664 hybrid or a combination of both test points. The Sigma puts flexibility, high fault coverage and simple programming at the fore. Thanks to the non-multiplexed pin architecture it is also possible to use fixtures and test programs from other test systems.

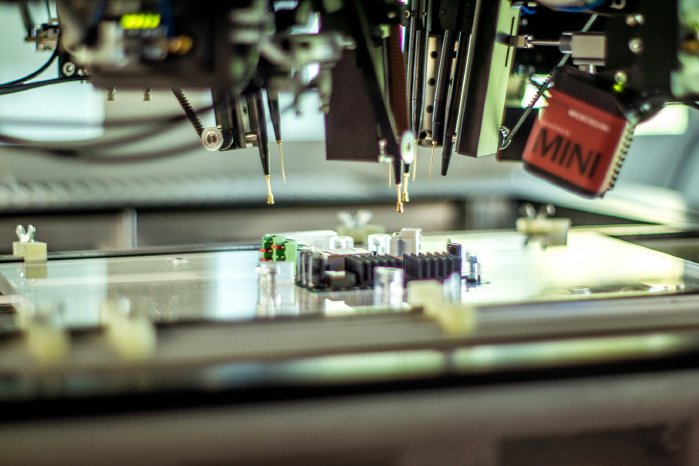

Be universal: the flying probe tester Condor MTS 505

The Flying Prober Condor, which can be used for all test strategies, will also be exhibiting Digitaltest at the Apex Show. Thanks to the four movable test heads it offers high adaptation depth and test coverage. The optional use of fixed test pins on the underside of the test object means you can also shorten the test time while increasing the test coverage. The Condor is equipped with a high-tech color camera (CMOS) to accurately determine the position of the probe and device under test (DUT). It is attached to one of the four test heads and contains optics, as well as lighting. The flying probe system can be used as an in-line tester and as a front loader (manual loading).

IPC APEX EXPO 2019

January 26-31, 2019

San Diego, CA

USA

Digitaltest booth 3533