For further optimization of material flow processes in production the remaining master roll parts of carrier or adhesive foil after cutting for specific customer order are transported by automated guided vehicles from the cutting machine (called "slitter") to a buffer zone. The cut parts (called "cheeses") could have a width of 100 to 1000 mm, diameter from 300 to 1200 mm and a weight of 8 to 1350 kg. A further requirement consists in transporting these cheeses in a vertical position rather then the normal horizontal position.

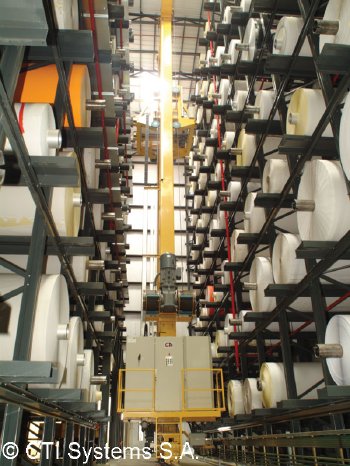

CTI Systems considered as an expert for the development and production of automated material flow and storage systems for heavy loads provided a global concept solution comprising four automated guided vehicles (AGV) and a high bay warehouse with one storage aisle. The AGVs will be equipped with a unique developed grab system. The roll pickup and further transfer to the high bay warehouse are executed without any external support. The high bay warehouse rackstacker takes the cheeses in the same vertical position and stores them following a dynamic "just-in-time" calculation of a storage place. This means that there is no fixed storage location. The storage place is determined automatically following the dimensions of the cheeses.

The entire concept is supported by CTI Systems developed software. Thanks to CTI's know-how, experience and highly qualified internal resources CTI supports an advantage in the area of process automation and software development as compared to competition. In the same context the flexible warehouse management system (WMS) developed for the 2005 installation has been updated.

The market segment of automated guided vehicles (AGV) represents an important market for CTI Systems. CTI's AGVs meet requirements and expectations to deliver an innovative and qualitative transport system in various industry branches i.e. aviation and manufacturing of agricultural machinery. The AGV systems feature full omnidirectional driving capabilities and are programmed to follow a series of floor-integrated magnets (guidance system). This high degree of automation considerably increases productivity and material flow becoming more secure for humans and materials as well as free from any source of error.

Entry date of service is subject to the availability of the intended building however, the plan is for May 2015. With this investment Avery Dennison secures moreover the flagship position of the Rodange site within the group.