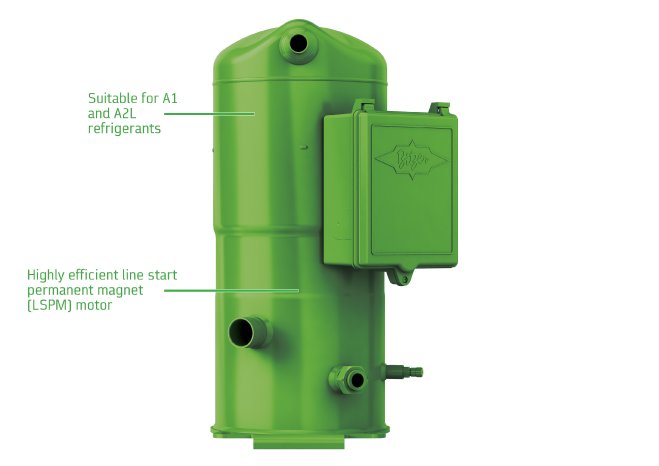

ORBIT (model range VL) and ORBIT+ scroll compressors from BITZER have been approved for serial production for use with the refrigerants R454B, R452B and R32 since February 2019 and are also suitable for operation with A1 refrigerants. This makes the specialist for refrigeration and air conditioning technology the first manufacturer in the world to supply scroll compressors with displacements of between 20 and 80 m3/h (50 Hz) for use with A2L refrigerants. These have only low flammability ratings and a low GWP. The familiar ORBIT series in the VA model range will continue to be available for operation with A1 refrigerants. ORBIT and ORBIT+ were presented as a world premiere at the Mostra Convegno Expocomfort trade fair in 2018 and are already integrated into the BITZER software (www.bitzer.de/websoftware), ensuring that they can be quickly and easily configured by customers.

BITZER customers will particularly benefit from the A2L approval of the ORBIT (model range VL) and ORBIT+ compressors: both series provide several years of planning security due to the low GWP values of the refrigerants R454B, R452B and R32. Before they were approved for serial production, the ORBIT and ORBIT+ scroll compressors demonstrated their quality and future-proof compatibility in extensive tests. In addition, they have been successfully qualified by important OEM customers in their qualification programmes.

BITZER ORBIT scroll compressors: powerful and versatile

The ORBIT and ORBIT+ compressor models feature displacements of between 20 and 80 m3/h (50 Hz) and are designed for air conditioning systems and heat pumps in particular. Their strengths include a wide application range, their high energy efficiency and a low noise level. All compressors in the series can also be operated at a fixed speed or using an external frequency inverter with variable speed (35 to 75 Hz). ORBIT and ORBIT+ scroll compressors can be equipped with the BITZER Advanced Header Technology (BAHT), providing customers with hundreds of potential tandem and trio assembly combinations. With the ORBIT Portfolio, OEMs can tailor offers to their customers, whereby the construction and manufacturing processes in the system construction can be designed largely the same. This saves OEMs significant costs in development and production. As the ORBIT and ORBIT+ series feature identical connection sizes, there is less design, production and logistics work involved in the development of a new generation of systems. This provides OEMs with maximum flexibility and efficiency.

This video offers more information on ORBIT scroll compressors: https://bit.ly/2w4hV1E

As a specialist for refrigeration and air conditioning technology, BITZER is present all over the world: with products and services for refrigeration, air conditioning and process cooling as well as transport, BITZER ensures optimum temperature conditions for trade in goods, industry processes and indoor climate control – always considering highest possible energy efficiency and quality. BITZER is represented all over the world with 65 sites in 34 countries – sales companies and production sites inclusively. Trade and service partners included, the BITZER network of manufacturing, development and sales extends to almost all countries in the world. In 2018, 3,500 employees generated a turnover of €740 million; expenditure for research and development totalled €37 million.

Overview of images

Images may only be used for editorial purposes. They can be used free of charge if the source is given – ‘Photo: BITZER’ – and a free copy of the publication is sent to us. Images may not be modified or altered, except to crop out the background surrounding the main subject.