.

• Expanded range of compressors for CO2, ammonia and HFO/HFO blends

• Comprehensive tests and qualification processes for HFO/HFO blends completed

• Risk analysis for additional products with A2L and A3 refrigerants successfully carried out

• BITZER software enables configuration of all semi-hermetic compressors, condensing units and heat exchangers with HFO/HFO blends

Following extensive testing and an intensive qualification programme, compressor specialist BITZER has approved several compressor series for HFO/HFO blends. The long-standing company will be showcasing several models that are now also designed for refrigerants with low global warming potential at the Chillventa 2016 trade fair at Nuremberg Exhibition Centre (hall 7, stand 330) from 11 to 13 October.

Refrigerants with low global warming potential (GWP) are becoming more and more important in the refrigeration and air conditioning industry in Europe and beyond. And this trend will only accelerate over the next several years. BITZER is therefore not only further developing its compressors and condensing units for use with natural refrigerants such as CO2, ammonia, hydrocarbons and HFO/HFO blends, but also adapting its service to meet current requirements. BITZER has also promoted the qualification and documentation of its semi-hermetic and hermetic compressors, its condensing units and its water cooled condensers with HFO/HFO blends. ‘HFO ready is more than just a term for BITZER,’ says Rainer Große-Kracht, Chief Technology Officer of BITZER. ‘It means that the compressor, the condensing unit or the condenser has undergone full qualification, which at BITZER tends to be extremely demanding. For instance, it can include intensive measurement of the performance data and extensive risk analysis, if the refrigerant in question belongs to the A2L or A3 category.’

Experience with HFO solutions

BITZER’s reciprocating compressors, semi-hermetic and compact screw compressors, and scroll compressors for series application are currently HFO ready. The long-standing company has gained a great deal of experience over the years with the everyday use of HFO applications – under a variety of operating conditions round the globe. ‘We therefore provide system suppliers with the opportunity to respond to end users’ demands and desires for sustainable, environmentally friendly refrigerants. In this way, system operators receive a solution tailored to their specific needs as well as high energy efficiency, reliability, serviceability and sustainability’, Große-Kracht continues.

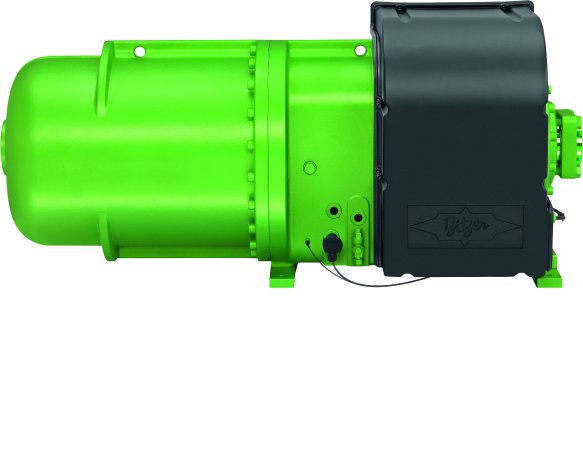

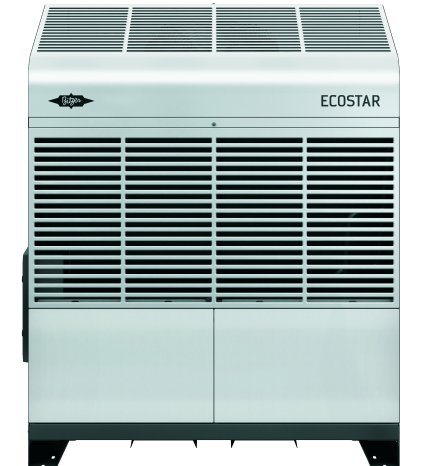

BITZER will be presenting the new CSVH2 compact screw compressor series approved for HFO/HFO blends to the general public for the first time at Chillventa 2016. BITZER’s CSH and CSW series have been approved for the R1234yf, R1234ze(E), R513A and R450A refrigerants since the beginning of 2016. BITZER has also further developed the ECOSTAR LHV5E and LHV7E condensing units with integrated ECOLINE VARISPEED reciprocating compressors. For instance, the LHV7E requires less refrigerant than its predecessor. BITZER has also optimised the LHV5E and LHV7E models in accordance with the F-gas Regulation and the EU’s Ecodesign Directive, and approved them for HFO/HFO blends. The long-standing company in Sindelfingen will also be expanding its selection of compressors for HFO refrigerants in the future: the CSVH3, CSVW2 and CSVW3 series will be HFO-ready by April 2017.

The Association of European Refrigeration Component Manufacturers (ASERCOM) certified 32 BITZER compressors and condensing units in 2015, thus confirming their efficiency and their high coefficients of performance. These include the ECOLINE reciprocating compressors, which are designed for use with the eco-friendly R448A and R449A refrigerants. BITZER was the first compressor manufacturer to fully test and document the two refrigerants, and has also integrated both of them into the BITZER software. This program makes it simple to configure systems and convenient to select compressors.

Overview of images

Images may only be used for editorial purposes. They can be used free of charge as long as the source is indicated – ‘Photo: BITZER’ – and a free copy of the publication is sent to us. Images may not be modified or altered, except to crop out the background surrounding the main subject.