Consisting of a transmitter with a high-performance red-light laser and a receiver, the device works completely autonomously, without additional accessories such as a PC or special software. The light array with its active width of 16 mm offers a resolution of 10 µm. The maximum range is two meters. Blanking represents an important feature. This function makes it possible to hide obstructions in the measuring field if necessary.

The IO-Link interface offers central data storage and management for simple and fast configuration – even for format changes during the production process. Using IO-Link the signals with numeric values are reliably and faithfully transmitted, for example in edge positioning or detecting diameters. These functions make the laser light array ideal for tasks such as precise position detection, object classification or simple part sorting by size or diameter. Evaluated are not just the light quantity of the especially homogeneous laser red light, but the location and position within the light grid.

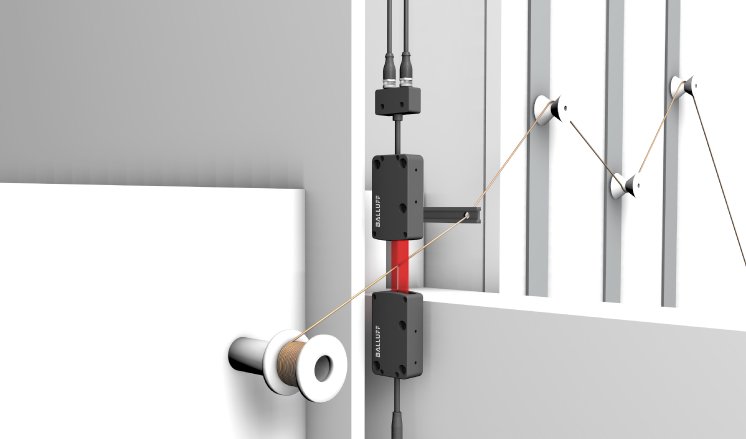

Quality assurance variables like object heights, gap dimensions or holes can be monitored. Precise detection of web edges is also possible, even with semi-transparent materials. Thanks to the compact form factor of emitter and receiver (each just 38 mm x 20 mm x 68.3 mm), now you can also implement applications in especially tight mounting conditions and on hard to access locations. An operating hours counter is also integrated in the sensor for not only monitoring processes with greater accuracy but also indicating maintenance intervals.