Drying times lasting several hours or days are unacceptable to foundries, and solutions such as mold dryers or curing stoves are contingent on additional investment. That is why the preferred method still for molds and cores in the medium and large-scale casting segments is to use alcohol-based coatings, which can be burnt off if necessary. This remains common to this day, though it is invariably associated with numerous risks. As a result, EHS protection on the one hand and economic considerations on the other are forcing foundries and their suppliers to act. Today our focus is on developing efficient water-based solutions.

SOLITEC™ HY for medium-scale casting

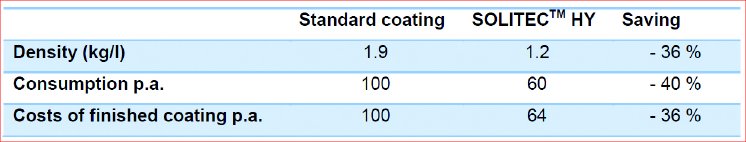

It is mainly in the medium-scale casting segment that foundries demand quick-drying coating solutions, which increase productivity and have not been designated hazardous. The patented coating paste SOLITEC™ HY from ASK Chemicals is water-based and can be diluted with alcohol. Unlike conventional alcohol-based coatings, the alcohol used for diluting has a higher fire point and is not classed as a hazardous material. Investment and costs for storage, insurance and transport are reduced due to the elimination of the dangerous goods classification. The high yield of the diluted coating (density =1.0g/cm³) offers further savings potential (Table1).

SOLITEC™ DI with wet/dry indicator for large-scale casting

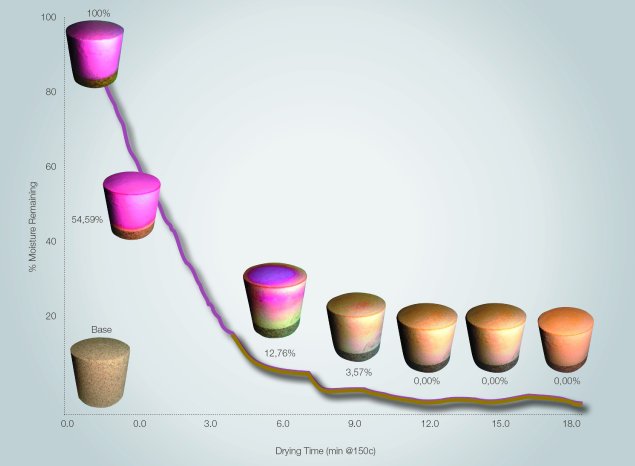

With SOLITEC™ DI, we have succeeded in developing a quick-drying coating that undergoes a noticeable color change once it dries. To prevent casting defects, complete drying of the coating layer is absolutely essential. SOLITEC™ DI changes color during drying and thus serves as a perfect wet/dry indicator and, consequently, as an in-process quality assurance tool likewise (Image 1).

Should sand molds or cores exhibit insufficiently compact areas, these areas will tend to absorb more moisture than the surrounding, better compacted, areas, with the result that they will require a longer time to dry. This is where the easily discernible color change helps optimize process safety and reduce scrap. Defective cores and molds are easier to detect and defective castings can be avoided.

You can find out more about SOLITEC™ Drying Technology at GIFA in Düsseldorf from June 16 to 20, 2015 in Hall 12, Stand A22.