IBS Coatings: Additional Coating Process Now Available

(pressebox) (Olching, 06.12.2010) LASER COMPONENTS now offers an additional coating technology: IBS coatings.

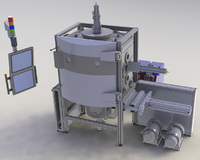

High-Quality Coatings - Ion beam sputtering (IBS) is used in particularly difficult coatings. With this process, the desired layer thickness can be produced very precisely and with a high reproducibility.

Another advantage of this process is that it produces very smooth and thus optically homogeneous layers as a result of the high kinetic energy obtained during layer deposition. The deposition rate, which is significantly lower than the rate of other methods, yields drift-free layers.

New Products - Our customers will benefit from the expansion of our optics production facility in many respects: In the future, they will not only be able to choose "their perfect coating" from all common coating technologies, but new products will find their way into our portfolio as well. This will include very steep filter coatings for high-power applications and low-dispersion coatings with reflection coefficients of R > 99.99%.

For more information visit our website at http://www.lasercomponents.com/...

Ansprechpartner:

Herr Sven Schreiber

Telefon: +49 (8142) 2864-27

Fax: +49 (8142) 2864-11

Zuständigkeitsbereich: Export Manager

Über Laser Components Germany GmbH: LASER COMPONENTS is specialized in the development, manufacture, and sale of components and services for the laser and opto-electronics industries. With sales offices in four different countries, the company has served its customers since 1982. In-house production at six locations in Germany, Canada, and the USA began in 1986 and is meanwhile responsible for about half of its turnover. Currently, the family-run business employs more than 120 people worldwide.

(203 kB) |

zurück zur Übersicht

zurück zur Übersicht