The LT40 Transfer System Enabling Success for Brembo

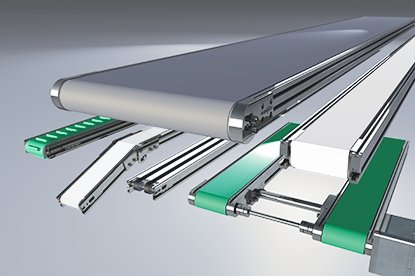

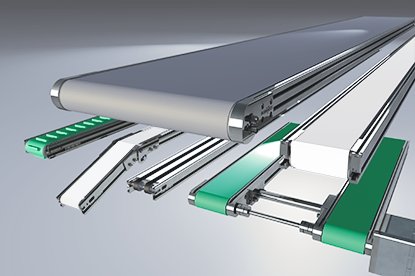

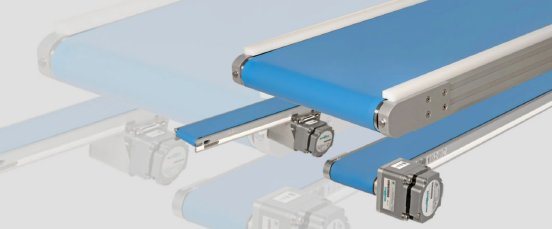

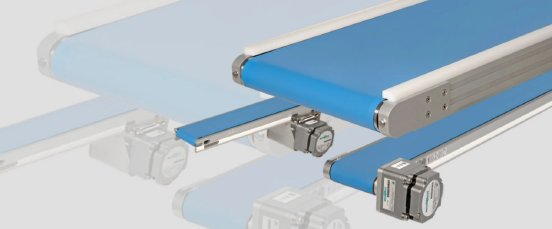

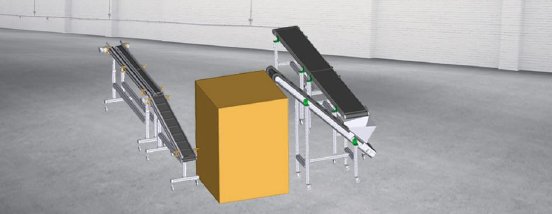

Brembo and Politecnico di Milano are setting new standards in production lines! The world-leading manufacturer of braking systems, Brembo, aimed to create a demo line featuring four processing steps, centering operations, and flexible line routing. How were these high requirements met within a limited space and with an aesthetic design using our LT40 transfer system? Find out more in our report!