From a safety perspective alone, compliance with the highest quality standards is an absolute must in the automotive manufacturing and component supply industries. Reliable 100% inspections are only possible with automated meas-uring and inspection technology. And, of course, the perfect quality inspection must also be designed with cost efficiency in mind.

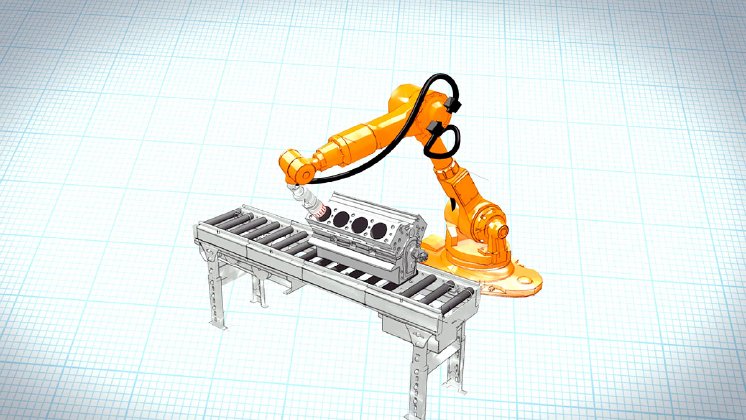

Robot cells designed with VITRONIC VINSPEC detect microdefects in the visi-ble, sealing and functional surfaces of complex metallic components. They can also inspect areas for which a visual inspection by the operator is difficult or subsequently impossible. For example, the surfaces of a drilled hole require inspection using an internal inspection sensor. 2D and 2½D sensor technology and, if needed, a customized handling robot are used to enable flexible visual inspection of a wide range of surfaces. The inspection results are documented and archived.

For complex components, such as cylinder heads and crankcases, the solu-tions on offer have, until now, been very complicated — consisting of several machine vision systems and a large number of sensors, and associated with significant investment costs. In these solutions, each and every change made to the components to be inspected requires a time-consuming, cost-intensive mechanical modification. The individualization of products in the automotive industry cannot be achieved with such inflexible systems.

Superior flexibility thanks to fast, easy changeovers

With VITRONIC robot cells, you can incorporate new or modified component types into the inspection process during production runs, simply by adjusting the inspection system software and reprogramming the robot program. This enables a fully automatic inspection of even the smallest production series. Fast response times during component changeovers and the possibility of inspecting small batch sizes mean that products can be highly individualized under the same conditions as an extremely flexible large-scale production sce-nario. The surface inspection offered by the flexible VITRONIC robot inspection cell brings us a step closer to the dynamic design of manufacturing processes as envisaged in Industry 4.0, even in relation to complex issues such as quality inspection.

The current status of the component is documented and archived by the in-spection system software. At the time of the inspection also the serial number of each component is acquired. The combination of inspection result and serial number leads to more transparency of the production process.

The newly developed inspection system features impressive efficiency at lower investment costs, while eliminating the need for mechanical modifications. It significantly reduces the time for changeovers, and enables greater flexibility.

VITRONIC will present the VINSPEC robot inspection cell with integrated, opti-mal inspection system at the "Hannover Messe" trade show from April 13 to 17, 2015 at booth 42 in hall 17.