PCMs lend themselves to specific cooling and warming conditions. In the case of cooling with frozen packaging, the risk is that the cooling period is not sufficient. By using PCM as a cooling agent, a longer cooling period can be achieved. The melting point is chosen so that an optimal cooling period can be maintained, not only temporary, but throughout the whole supply chain - up to the end user. In addition to being used during transportation, ClimSel can be applied in energy storage in buildings, temperature control in garments and temperature stabilization in electronic components.

Not only has the wide range of fill weights (from 30 mL to 1.000 mL) imposed high demands on the filling, but also the high abrasiveness of the salt crystals in the media. To meet those requirements, the filling pump 2RD40 Pharma from ViscoTec, which uses the progressive cavity pump principle, was chosen.

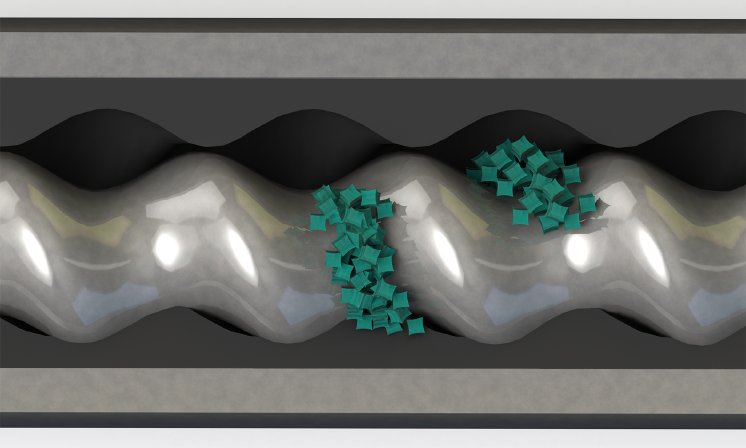

The progressive cavity pump is particularly suitable for conveying and filling abrasive and solid-containing media. The abrasive solids are transferred in a product- and pump-gently way in the carrier medium through the chambers between the rotor (stainless steel) and stator (elastomer). The friction coefficient between rotor/stator combinations is reduced trough the tribological film of a few µm. Therefore premature wear is avoided.

As an illustration an everyday example:

When cleaning the window the water is forming a tribological film between the glass and the rubber lip of the puller. This film ensures that the granular dust and dirt particles on the window don’t damage neither the rubber lip nor the glass.

As progressive cavity pumps are dosing pulsation-free and under low pressures, in this case approx. 3-4 bar, also concentrations of the filler are avoided. Furthermore the progressive cavity technology operates without metal-to-metal contact between the rotating parts.

The dosing geometry allows for a constant volume per turn (proportional to the angle of rotation) resulting in a uniform product flow. This prevents premature sedimentation of fillers. The volume is clearly defined by the angular degree; no backflow or undercuts (uniform distribution of the solids) are existing. This technique results in a pressure-constant, linear pump performance curve. A clear statement can be made about the relationship between revolution, time and delivery. Therefore, a wide range of different volumes can be filled using only one pump - with safe processing and repeat accuracy.

All these advantages are adopted by manufacturers of tubular bag filling machines, for example the company Hastamat located near Frankfurt, who relies on the reliable and precise technology of ViscoTec. A typical configuration is the assembly of a progressive cavity pump mounted on top of the machine, which is filled via a container. The filling nozzle at the end of the pump is directly mounted in the forming tube of the tubular bag filling machine. After filling, the filling nozzle is closed with a plunger to prevent dripping of the product. In this way, a clean seam for the sealing of the bag is ensured.

Climator Sweden AB was founded in 1979 – at the same time the phase change material ClimSel with excellent energy- storage properties was launched. Since then the product has been successfully developed, produced and marketed on the global market.

Climator Sweden AB, Mejselvägen 18, SE-54134 Skövde, Sweden

HASTAMAT Verpackungstechnik GmbH is one of the leading manufacturers of packaging machines and packaging lines, having its production centre in Germany and a worldwide sales network. Modern and rational manufacturing methods, as well as an extensive quality management form the basis for technically perfected and economically high quality machines and lines.

Hastamat Verpackungstechnik GmbH, Naunheimer Straße 57, 35633 Lahnau