SorTech has been successfully working for several years on the problem ‘Cold from heat’ – with power- and CO2-saving adsorption chillers which are fuelled by unused low-temperature heat. SorTech’s intelligence resides in the adsorption modules: They are equipped with lamella-type heat exchangers coated with an adsorbent – small silica gel or zeolite ‘beads’. The process is environmentally harmless as it uses pure water as coolant. Application of our compact cooling units can often save more than 80 per cent of energy and operating expenditures compared to electric power-driven chillers. Currently available cooling units, however, have relatively large footprints (ca. 1.5 cbm) and are mainly used in stationary applications.

Light-weight solutions – a must for enhanced mobility and flexibility

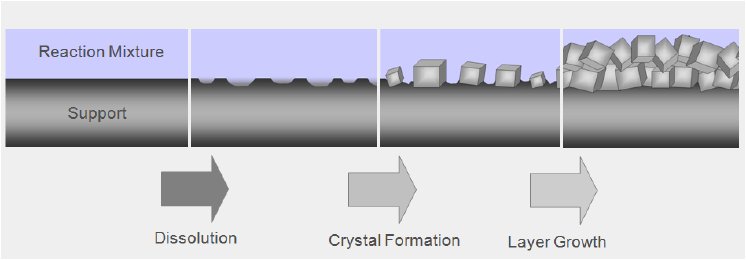

The request for energy-efficient and intelligent solutions for mobile applications has kept SorTech researchers and developers busy for quite some time. Their efforts have led to the development of PST – a novel zeolite-coating technology. The PST process allows for direct crystallisation of zeolite on the surface of a carrier material. This allows for markedly higher power densities compared to conventionally coated carrier materials and the on-crystallised zeolite layer with a robust bond to the carrier material provides excellent corrosion protection. There are no binding or adhesive layers required which in turn ensures optimal heat transfer. This innovative material configuration permits reduction of heat exchanger footprints – without output loss – by a factor of 25 and considerably reduces unit weights.

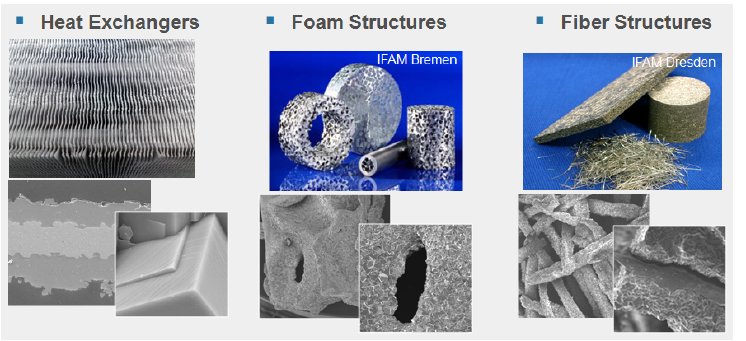

Another advantage of this new technology is that optional designs can be coated to achieve their best-possible adaptation to a given application. Carrier materials include classical (lamella-type) heat exchanger, customised foam or sponge mouldings or fibre materials – there are almost no limits to geometric forms.

Fundamental research into composite materials has been completed and has reduced adsorption equipment footprints and this made it suitable for mobile applications in vehicles. The new PST processing technology will be presented for the first time in Frankfurt am Main at the ISH trade fair.

Creative applications sought-for

‘Our current challenge is to improve PST technology to achieve market maturity, in a joint effort with industrial partners’, says Walter Mittelbach, CEO SorTech AG. ‘We are in intensive discussions with potential development and sales partners in various sectors but have not made a final decision on the initial fields of application. The market potential of PST technology is enormous’, Walter Mittelbach adds. ‘In Europe alone, a market with a volume of several billion euros may emerge by 2020 which at the same time makes a considerable contribution to the turn in energy policy.’

Whether in aircraft, electric cars, trucks or caravans – ‘SorTech PST-inside’ has the potential of soon becoming a new quality seal for eco-friendly cooling or heating.