The primary objectives of any air conditioning are optimal values in terms of temperature and relative humidity with an increasing focus being placed on the reduction of CO2 concentration. Furthermore, other parameters such as increased air tightness and insulation of buildings or heat recovery make more and more demands to building automation, i.e. to climate control.

The need to create and maintain overpressure in cleanrooms, for example, to ensure a certain flow direction, to adhere to defined limit values, or to provide minimum air quantities entails additional requirements with respect to air-conditioning and ventilation technology: this is the case when the focus is on the safety of production processes or the quality of products. The increased demands on air-conditioning systems are reflected by the rapidly growing number of standards, directives, and regulations.

Ecological and economical aspects

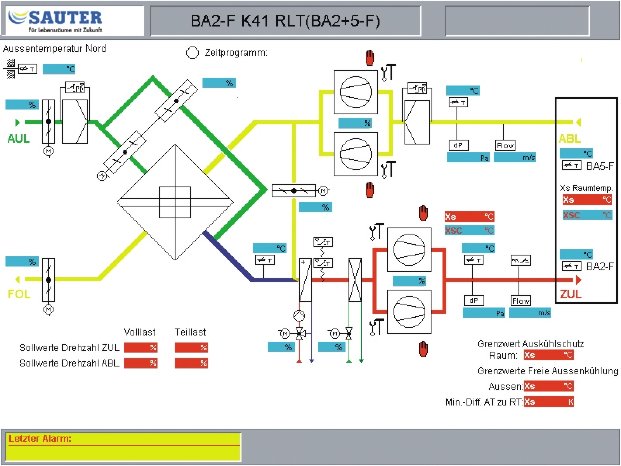

All these issues are directly related with energy consumption, i.e. with cost. Against this background, SAUTER-Cumulus develops, produces, and distributes energy-efficient complete solutions for intelligent building automation. “This is not possible without adequate sensors for temperature, humidity, CO2, and volumetric flow measurement”, explains graduate engineer Claudia Zeller of SAUTER-Cumulus GmbH. In conjunction with energy consumption, the product manager of a worldwide leader in building automation particularly addresses volumetric flow measurement, being directly used for fan operation in air-conditioning systems, i.e. for operation of those components which transport the volumetric flows through the ventilation system. In terms of energy, this means that the fans convert the electrical energy absorbed into pressure and motion energy. Consequently, the core component of intelligent building automation is a control system allowing minimization of the required air volumes to the demand required for maintaining the air quality and the thermal environment. This includes frequency-controlled fans or permanently activated air flaps.

For accurate measurement of the volumetric flows over a wide measuring range from almost zero, as is the case when the fans are started, to the maximum, which in systems of this type can be between 7 and 8 m/s, the previously used measurement methods such as orifice plates are increasingly less suitable. Flow sensors based on thermal anemometer technology represent an adequate solution to fulfill this task. The measurement method, which is also known as hot-wire anemometry, allows direct detection of the volume flow rate.

In flow sensors like the SS 20.250 or SS 20.260 from SCHMIDT Technology, the sensor element is continuously heated to a temperature that is maintained, via a regulating circuit, at a constant value of 40K above the medium’s temperature. The energy necessary to maintain this temperature relative to the flowing medium, i.e. air, is then measured. The output signal, which is quite strong over a wide measuring range, indicates the existing flow velocity.

“The advantage of these sensors for ventilation and air-conditioning applications is that they make it possible to specifically react to variations in the air requirements”, confirms Claudia Zeller. An accurate measurement of the volumetric flows and not least its documentation is essential, in particular in areas where certain requirements with regard to production processes, product quality, or hygienic air conditions need to be met. Furthermore, a demand-responsive, minimized air flow holds an enormous potential for saving energy.

Use in practice:

Volumetric flow measurement in far Japan

It is not only since the Fukushima disaster that energy-efficient operation of air-conditioning systems has been an important issue in Japan. It is, in fact, a statutory requirement. One example of progressive air conditioning can be found in the Iino building (www.iino.co.jp/iinobuilding) in Tokyo where a total of 45 dumbbell sensors of the SS 20.500 type have been installed for monitoring and regulation of the air-conditioning system. This is the result of a previous, meticulous analysis of all available measuring systems, eventually showing that the SS 20.500 was able to meet the high requirements (1% accuracy!!). The objective of this endeavor was to be approved as a “top-level office” in terms of CO2emission. Compliance with the criteria has been certified by an external certification body: reduction in CO2 emission of 46% compared to similar buildings.

Another model object with respect to energy efficiency is presently being built in the exclusive commercial district of Marounuchi in the city of Tokyo: the “New Tokyo Post Office”. SCHMIDT flow sensors have been selected for this project because they do not only provide extreme accuracy, but are also able to detect the direction of flow (backflow). This is not possible using conventional measuring systems.

Appendix:

Overview of the most important standards for volumetric flow determination:

DIN EN 13779

- Ventilation of non-residential buildings – General principles and requirements for ventilation and room-conditioning systems

- Dimensioning of the volumetric ambient air flow of free and fan-supported ventilation systems per person or per surface unit

DIN EN 15251

- Indoor environmental input parameters for design and assessment of energy efficiency of buildings – addressing indoor air quality, thermal environment, lighting and acoustics

- Dimensioning of the volumetric ambient air flow of fan-supported ventilation systems, criteria for indoor climate monitoring, different indoor climate categories for residential and non-residential buildings

DIN EN 15232

- Energy efficiency of buildings – Influence of building automation and building management

- Energy-efficiency classification of residential and non-residential buildings

DIN EN 15242

- Ventilation for buildings – Calculation methods for the determination of air flow rates in buildings including infiltration