In contrast to the core yarns established hitherto on the market, dual core yarns consist of three components: a mostly elastic polyurethane filament such as Lycra®, creora® or INVIYA® I-300, a multifilament such as Lycra® T400® and the sheath material of staple fibres, mainly cotton. They are required for denim applications and spun in suitable counts. The complex yarn structure presents a particular challenge to the splicing process when winding. The staple fibre sheath on the dual core yarn is proportionately much thinner than for single core yarns, for example 70:30 instead of 95:5. A good spliced joint is only obtained if the elastic core does not spring back when cut and the filaments are once again uniformly sheathed by the staple fibres following splicing.

Here the Autoconer can play optimally to its strengths in splicing. The dual core spliced joints on the Autoconer X5 produce a joint that is identical to the yarn. They have the same elasticity as the yarn, as both filaments can be joined reliably to one another. They are visually inconspicuous, as the sheath fibres securely cover the filament core. Uniform dyeing of the yarn with the resulting top quality of the final article is assured, as are maximum efficiency and processing reliability in warping and weaving.

Preconfigured piecing cycles and coordinated splicing components

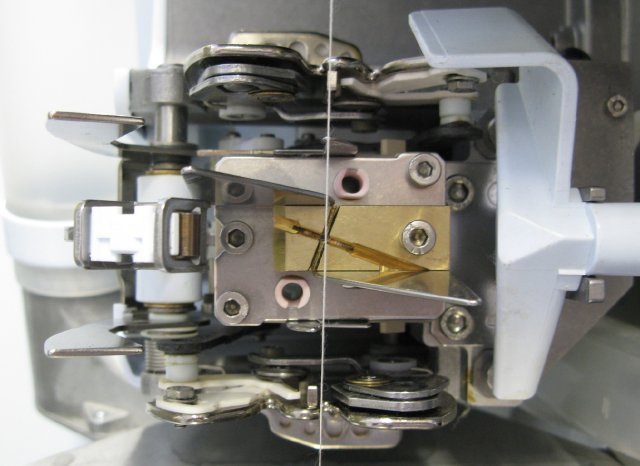

The splicer in the Autoconer has single-motor control, so the timing in the splicing process can be optimally adapted. Following the cut, the dual core yarn is fixed quickly and securely. The opening and splicing times are coordinated to one another so that no yarn element is lost. The piecing cycle is optimised for the splicing of core and dual core yarns and can be selected simply at the Informator at the touch of a button.

For denim dual core applications, the Schlafhorst technologists recommend the injection splicer with elastic module and setting and the LC5 / 2.5 EB2 prism as a set. The opening tube is chosen to suit the yarn structure. Fine-tuning is possible at the Informator by setting the optimal opening and splicing parameters.

Autoconer winding and splicing process ensures quality and reliability

When winding dual core yarns on the Autoconer X5, Schlafhorst customers achieve perfect results, as the following example from the production of a leading denim manufacturer demonstrates. The company winds CO/PES/elastane, a typical dual core denim yarn, in a count of Ne 16.

The Autoconer is configured as follows:

- Direct link to Zinser 351 ring spinning machine with core yarn device

- PreciFX

- Injection splicer

- Prism: LC5 / 2.5 EB2

- Ceramic shears

- Elastic splicer setting:

In this linked system the Autoconer X5 produces visually perfect spliced joints with an excellent, wholly uniform appearance. At 95-98% the average splice strength attains nearly the same strength as the yarn. The colour impression of the dyed woven fabric is flawless.

Perfect link with the ring spinning machine

In a directly linked system with the ring spinning machine, the demands made on winding go a stage further. The Autoconer overcomes this obstacle with ease and processes the lively yarn fresh from spinning gently and reliably. The bobbins are delivered to the winding units with the yarn end securely fixed on the tube tip. Reliable yarn end pick-up and transfer, sensor monitoring of the process sequences - these all contribute to a highly reliable winding process. Thanks to the very low level of stoppages and red light occurrences, the presence of operating staff is virtually superfluous; production without operators becomes a reality.

Maximum efficiency in the weaving mill: yarn break rates down to almost zero

The dual core yarn packages of the Autoconer perform outstandingly in unwinding in the weaving mill. Yarn breaks in weaving were analysed over a fourteen-day period in a study. It emerged that not a single yarn break occurred in the spliced joint. The yarn break rate was thus virtually zero when it came to splicing.

Non-stop weaving with Autoconer packages

The actual yarn break rate of the tested dual core yarns in the observation period was between 0.3 and 0.5 yarn breaks per 100,000 picks. Such low values are typical of PreciFX packages, which run especially smoothly as they are optimally adapted in structure, shape and build to the requirements of downstream processing. At the present package running lengths (100,000 m) and pick insertion rates (700 m/min), this meant that the weaving machines ran for approx. 20 hours non-stop before a yarn break occurred.

Conclusion:

The Autoconer X5 is the ideal winding machine for processing demanding dual core yarns. With perfect spliced joints and optimally constructed packages, it ensures minimal yarn break rates in downstream processing and garments of flawless quality.

About Schlafhorst:

Schlafhorst has been a trailblazer in the production of staple fibre yarns for 130 years. As the market and innovation leader, the textile machinery manufacturer offers solutions for the entire spinning mill line right up to the quality package. World-famous brands like Zinser, Autocoro, BD and Autoconer, together with unique process competence, make Schlafhorst the partner of choice for successful textile companies. With production plants in Germany, India and China as well as an international service and consultancy team, Schlafhorst fulfils its mission: to make spinning mills across the globe more efficient, productive and economical.