Focus on preserving resources and energy efficiency

"The starting point for developing the new coating system was the requirements placed on component surfaces that are continuously increasing in quantity and complexity. The annual losses caused by corrosion and wear alone total around 4.5% of the gross domestic product in Germany. Protecting resources and the effi-cient use of energy are also becoming more and more important", said Dr.-Ing. Tim Hosenfeldt, Director of the Surface Technology Center at Schaeffler. Coatings ori-ented towards the application and the needs of customers can optimize the surfaces of components in such a way so as to minimize friction and wear thereby considerably reducing losses.

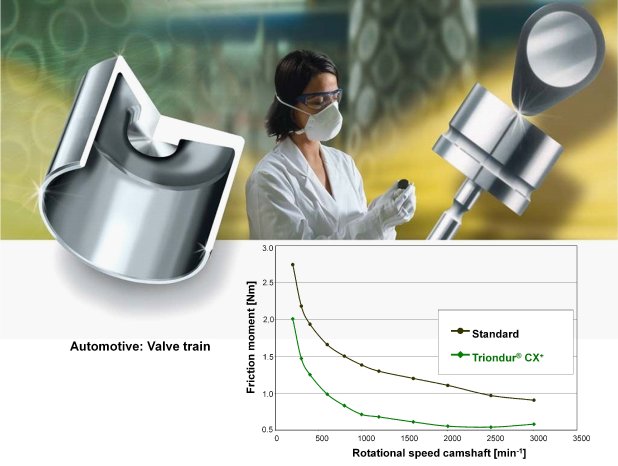

Triondur® CX+ combines three outstanding characteristics in one coating: minimal system friction and maximum wear resistance at coating thicknesses from only one to four micrometers. Triondur® CX+ is a hydrogenous doped amorphous carbon layer and is applied using environmentally-friendly PVD and PACVD vacuum processes. The nanopatterned Triondur® CX+ coating system is a new type of coating that enables the layers to be very precisely adjusted to the existing specific tribological and mechanical requirements by selecting the structure and the doping of the individual nanolayers, something that cannot be achieved with existing homogenous materials. This means it is possible to simultaneously achieve high abrasive wear protection and high toughness. The performance of Triondur® CX+ in terms of resistance to temperature, corrosion, and chemicals is considerably higher than that of conventional carbon-based layers (often also known as diamond-like carbon). This means the range of applications and therefore the added value for customers is also considerably higher.

With high quantities in volume production in the automotive and mechanical engineering sectors

With Triondur® CX+ , we have succeeded in halving the friction losses in the valve trains of passenger cars over the entire operating life in a customized combination with engine oils used all over the world, thereby cutting CO2 emissions in automo-biles by a valuable one to two percent. Triondur® CX+ enables rolling bearings to operate without wear and at low friction under extreme conditions. This means the friction values in spherical roller bearings can be cut by 45% and the bearings have the same low friction values in insufficient lubrication conditions as those they would only achieve under sufficiently lubricated conditions. Since only one friction partner has to be coated, e.g. the tappet or the bearing rollers, Triondur® CX+ can be used as a modular and cost-effective solution. The innovative force and added value for customers are reflected in the rapid expansion of the coating system on the market and the continuously-increasing quantities of parts supplied with the coating, which have already reached 20 million per year.