Using the Heidelberg Inline Converting System ICS 670 the new developed carton has been printed from roll to finished die-cut within one single pass. Processing this project, two high-end providers came together which complete each other perfectly.

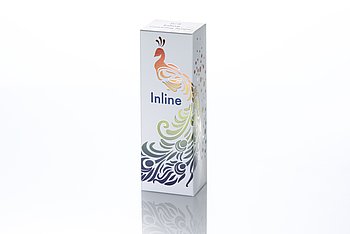

Especially the performance of the Scheufelen SBS board phoenolux, its whiteness and outstanding printability has the optimal prerequisites to show ability and performance of the Heidelberg inline web press at its best. The design of the carton box, containing information from both companies, was agreed within a few days and printing could get started. Several thousand reference boxes were produced for the use of sales and marketing departments in both companies.

First customers of Scheufelen already got the chance to evaluate the quality of the finished paperboard. They were impressed by beauty of the design with contrast colours defined by the luxury white surface of phoenolux, finalised by an elegant cold foil finishing. The functionality of the box is supported by perfect folding characteristics of phoenolux by Scheufelen, as well as by the efficient creasing process of the Heidelberg FCL.

AT A GLANCE:

Printing machine:

Heidelberg ICS 670 combined with a Heidelberg FCL 670 – Inline Converting System for ultimate efficiency in folding carton converting.

Material/Substrat: phoenolux c1s / 300 gsm

Printing process / Inline-production: Due to the modularity of the Heidelberg ICS the process includes various printing and value adding processes. The folding cartons were produced from roll to die-cut in one single pass, including the following process steps:

- 5 colours flexo-printing on front side (CMYK and special colour – blue)

- Solid black flexo-printing on backside

- Silver cold foil

- Gloss varnish

- Iriodin varnish

- Creasing

- Flatbed die-cutting

Your full service partner for high-end web printing presses Heidelberg offers tailored inline solutions for highest efficiency in folding carton converting. Whether from roll to roll or roll to the finished die-cut – Heidelberg web fed presses and die-cutters offer highest flexibility in printing and value add processes. Heidelberg web presses save costs and waste through inline production and one pass productivity by integrating multiple single operations like flexo, gravure- and screen printing, hot foil embossing, hot foil stamping, cold foiling and laminating.

Web printing solutions from a single source

With our core competencies in the fields of design, engineering, assembly, printing and service as well as our more than 90 years of experience in the folding carton industry you have a strong partner for your complete solution.

Our machine portfolio: Heidelberg INTRO, ICS, CCS and FCL - tailored to customer requirements

Industries: folding carton, liquid packaging, lottery tickets, flexible packaging

Substrates: paper, carton board, aluminum

Company contact:

Heidelberg Web Carton Converting GmbH

Am Forst 17 // 92637 Weiden // Germany

Thomas Geiger, Sales Director Web Carton Converting

Tel. +49 961 39 39 408 // thomas.geiger@gallus-group.com