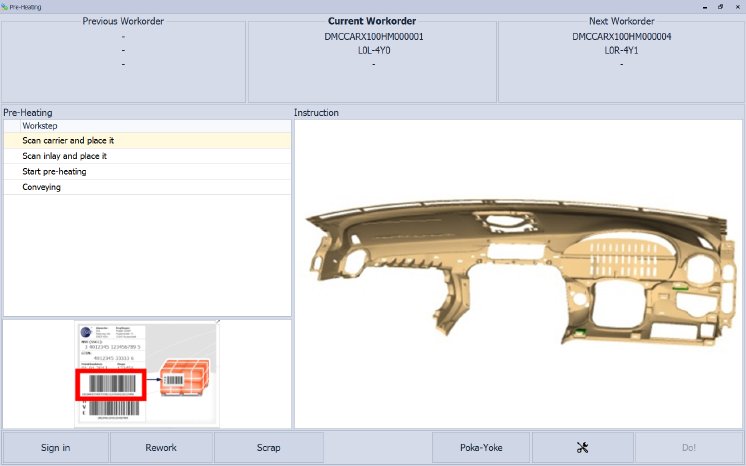

Flexible and multi-leveled workflows are indispensable to efficiently assemble products with many variants on the line. HYDRA users can now map the production procedure for a particular variant using the Dynamic Manufacturing Control (DMC) module. With DMC functions including product specifications, the digital image of the production process including relevant work steps can are stored in HYDRA.

Decentralized architecture

HYDRA DMC provides all necessary information for the relevant workstations in the required cycle time and, if required, intervenes in the process by using a powerful sub-system, the so-called Dynamic MES Weaver (DMW). Individually designed Dynamic Line Panels (DLP) easily guide the operator through the specified process. The process logic, located in the periphery, guarantees a continuous production of the assembly line even if the network has failed. DMC is fully integrated into the MES HYDRA environment and ensures that data, collected from the assembly lines, can be combined and evaluated with further information from production without interfaces.

Increased flexibility with DMC

Assembly processes for products with many variants require on one side rapid working cycles and on the other, a continuous flow of information. The information flow contains, apart from digital working instructions, control commands for the connected periphery like tools, pneumatic screwdrivers or Pick-by-Light systems. Up to now, head controls based PLC technology organized intricate workflows. However, in the age of Industry 4.0 production companies require increasing flexibility that cannot be managed with PLC technology. This flexibility is needed to produce efficiently and inexpensively small batch sizes.

Sequential production has been firmly established in the automotive sector. Other industrial sectors have discovered product configurators and assembly lines that also bring along increased flexibility to the manufacturing process.

HYDRA DMC incorporates new structural elements to expand the HYDRA basis and also contains application components and interfaces for the periphery. The new product already raised a lot of interest when it was introduced during the annual conference of the HYDRA Users Group (HUG).

More information on HYDRA DMC: http://mpdv.info/dmcen

Manufacturing Execution Systems (MES) support production companies to improve efficiencies in their production processes, increase productivity and thus to secure or enhance their ability to compete. A state-of-the-art MES puts companies in the position to record and evaluate data along the complete value-added chain in real-time. People in charge can therefore react instantly to unforeseen events in the daily production routine and put in suitable measures. The MES supports on all levels short-term and far-reaching decisions by providing a reliable data basis.

HYDRA, the modular structured MES by MPDV, features an extensive functional range and meets all requirements stated in the VDI guideline 5600. Individual HYDRA applications based on a central MES database can be combined without the use of interfaces. Thus, HYDRA guarantees a 360-degree view on all resources in production and can incorporate overlapping processes. Powerful tools for configuration and customization ensure that HYDRA can be modified in order to cater for company and industry specific requirements. HYDRA can be integrated into existing IT landscapes and is used as a link between production (shop floor) and the management level (e.g. ERP system). Production companies are particular reactive using an MES system like HYDRA and therefore remain competitive - especially looking at Industry 4.0.