3D metal printing continues to gain ground

The new technology enables entire processes to be rewritten from scratch. The technique has clear advantages, ranging from the production of complex geometries, the processing of materials that are difficult to machine, and the manufacture of components without the use of tools within an extremely short period of time and with very little material waste. Furthermore, it allows design changes made at short notice to be implemented quickly and easily. As a result, clients in the motor sport industry can now maximise their use of the development period specified by the FIA. Additive manufacturing enables weight to be reduced by up to 30% in comparison with conventional components. Moreover, groups of components which were previously complex to process can now be produced as a single piece following minor design modifications. Besides being cheaper, this saves on the need to use joining techniques which are usually crucial during the manufacture of such components.

EOS M290 – reliable and intuitive

The introduction of the EOS M290 marks the first time that toolcraft has chosen to work with a different machinery manufacturer. The benefits of the new EOS system include extended monitoring features for quality assurance. A camera is directly integrated into the process chamber, where the sophisticated precision parts are produced, virtually in a 3D effect. This requires a laser to melt metal layer by layer in a powder bed. The camera takes single images to monitor this process, ensuring a high level of quality management. In addition, the user-friendly offline job preparation function simplifies the task of handling complex parts and large job files. The machine itself features an intuitive, task-based graphical user interface.

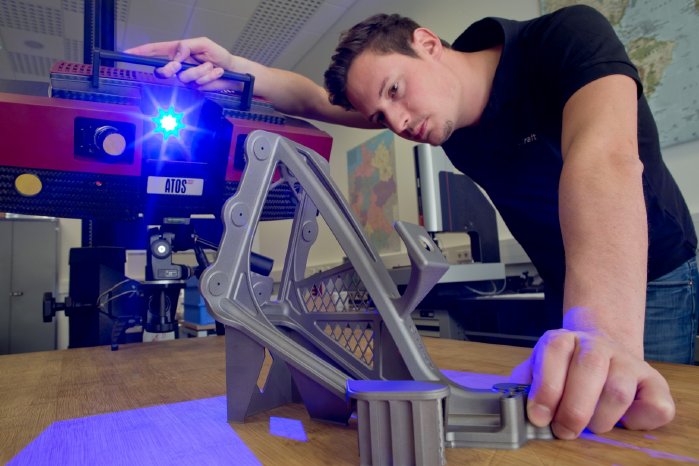

Verifiable quality for a wide range of industries

"The new machine from EOS is enabling us to meet our clients' requirements even more effectively," says Christoph Hauck, managing director of toolcraft. "The integrated camera system allows the quality to be monitored precisely during the production process." The final inspection and optical measurement tasks are performed exclusively by qualified staff. The quality of the components can also be quickly and reliably verified using a non-destructive surface testing system. As a result, toolcraft's metal laser melting division fulfils NADCAP requirements and is capable of producing high-quality precision parts for use in a wide variety of industries and fields of application.