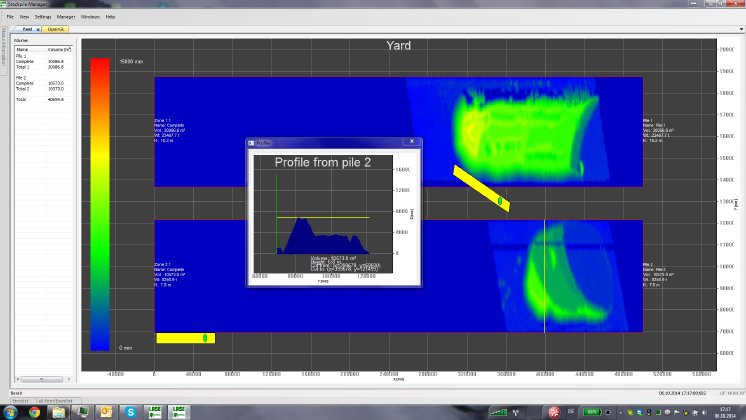

The system for heap volume measurement determines information like e.g. volume, 3D profile, peaks by using 3D laser scanners from the LASE 3000D-S-13x Series, which are installed on top of a stacker/reclaimer machine. In total two machines have been equipped with laser scanners at Adani, whereof three piles can be measured simultaneously. The laser data information from both machines are shown within a manager application. Here all different heaps/piles are displayed clearly and a segmentation of the material is possible, too. Due to fulfil specific customer needs, weight measurement data will be also recognized within the manager application.

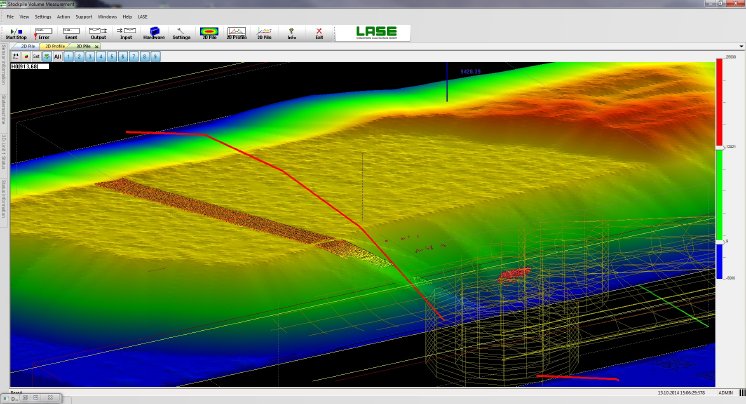

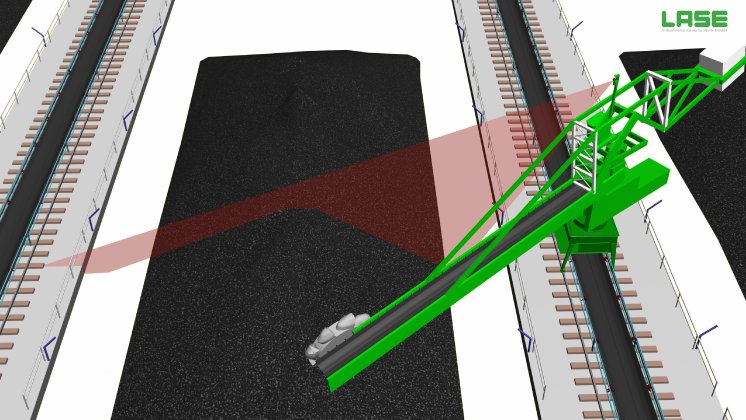

Depending on the heap-size, one (or more) 3D-laser scanner is installed on a machine for the realisation. This scanner is „looking“ above from the machine on the heap and scans the heap profile. In connection with the current stacker position a 3-dimensional image of the whole heap profile can be developed and compared to a „0-profile“within the application software, which has been taken during the calibration. Out of the obtained data the LASE CEWS application software calculates the profile and the volume of the heap precisely. The current filling level of each single field is transferred to the process control system, which recognises the removal/supply of material automatically.

Increasing numbers of customers need to automate their stackers and reclaimers within the raw material stockyards. In order to drive the machines automatically, it is necessary to know the profile of the piles on both sides of each machine. For this purpose 3D laser measurement technology is the most suitable technology.

The system can be operated intuitively due to user-oriented dialogue control and configuration wizards for simple commissioning. The software analyses the raw data and divides the measured volume into a grid pattern. Then the current filling level of each single field is transferred to the process control system. By this information the process control system recognizes the removal/supply of material automatically. Important state messages are logged and clearly displayed for additional documentation purposes. For integration in production plants all common interfaces are available, too.

The application has a high versatility and can be used for volume and profile measurements in several types of bulk material storages. This specific software derives from the product line CEWS Bulk Volume Module.

Find out more on our product site...