The automotive industry always has been shaped by current trends and continuous efforts to improve product performance and achieve consumer satisfaction. In the past decade the protection of the environment and the trend to compensate for the threatening shortage of fuel has intensified leading automotive manufacturers to lighten up their motor vehicles to boost the efficiency of both their automobiles and their manufacturing. Dyneon's fluoropolymer expertise is of enormous service to the automotive industry, producing many very useful advanced materials.

3M Dyneon Compounding Technology

One of the latest solutions developed by Dyneon employs Dyneon's Compounding Technology to incorporate innovative micro particle fillers with 3M Dyneon PTFE. The first product application, radial shaft seals, is currently undergoing intensive testing at the Institute of Machine Components at the University of Stuttgart. The results to date have been very promising as Prof. Dr.-Ing. habil. Werner Haas, head of the Sealing Technology department at the Institute, explains: "Some of the advantages compared to component materials currently available on the market include remarkably low permeation, improved resistance to friction and wear as well as smoother finishes. The new high-tech composites produced with this technology perform better in virtually every respect, saving fuel for better economy and greater sustainability, while benefiting consumers and manufacturers through their improved longevity and processability."

Other targeted application fields are flat gaskets. They show excellent resistance to deformation under load when produced with the new compound technology.

Energy efficient Primer-Free FKM-PA 46 composites

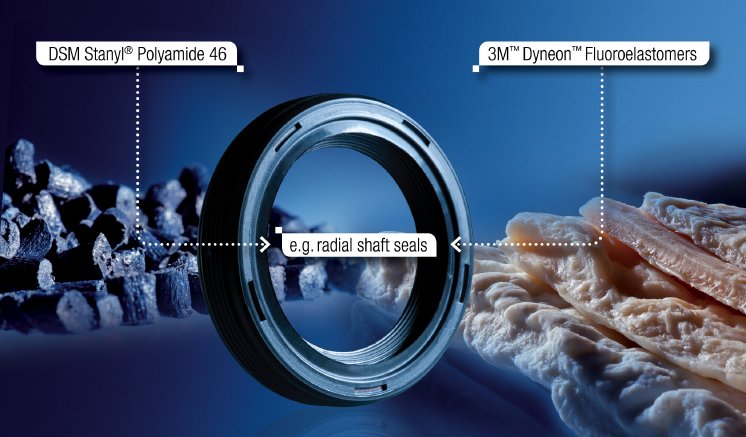

Primer-free FKM-PA 46 component material is lightweight, very strong and it easily stands up to high heat (200 °C) and aggressive substances, such as oil and fuels, making it a lighter, very viable alternative to metal and metal-elastomer composite materials for the automotive industry, particularly, for power train components. It is manufactured from DSM Stanyl® polyamide 46 and 3M Dyneon fluoroelastomer using an efficient dual-component (2K) injection molding process, prior to vulcanization.

The material's composition is twofold but its manufacturing advantages are manifold, largely eliminating the need for the expensive, environmentally unfriendly and often complicated processing that is typically required for metal parts. As the manufacturing process is less complex, the new material combination allows manufacturers to increase product quality consistency significantly while reducing the use and thereby the disposal or recycling of lubricants, cleaning agents and other manufacturing materials. "Our automotive customers have been delighted with the benefits, especially the weight reduction and durability plus the sizeable savings, not only driven by material cost but also by simplified and more sustainable production processes" says Ralph Ramaekers, Global Manager Powertrain at DSM Engineering Plastics B.V.

Glass Bubbles iM16K for injection moulding and extrusion

As additives to polypropylene and polyamide in demanding injection moulding applications, the Glass Bubbles allow for optimised plastic formulations with even lower density without making sacrifices in terms of durability or other physical properties. The product, which was specially developed for compounding and injection moulding processes in the plastics industry, boasts an isostatic compression resistance of over 1,100 bar (16,000 psi).

At a density of just 0.46 g/cm3, these innovative spheres can help reduce the weight of plastic systems, depending on fill level and formulation, by up to 18 percent. The lower weight is complemented by improved productivity: as the Glass Bubbles are hollow, less molten polymer needs to be cooled. This means that cycle times are shortened, by up to 25 percent. Alongside this, the dimensional stability of the components is improved, which results in fewer deformations and thus less waste.

Watch our latest Videos on the primer free bonding FKM PA 46: www.dyneon.eu/2k-project

About 3M

3M captures the spark of new ideas and transforms them into thousands of ingenious products. Our culture of creative collaboration inspires a never-ending stream of powerful technologies that make life better. 3M is the innovation company that never stops inventing. With USD 30 billion in sales, 3M employs about 84,000 people worldwide and has operations in more than 65 countries. For more information, visit www.3M.com