Even untrained personnel can quickly replace worn vanes using only a screwdriver and tweezers. Once the cylinder screws on the rear bearing cover have been loosened and the rollers removed, replacement is easy. The complete maintenance is finished in a few minutes, much quicker than exchanging the whole motor in the system. The patented vane exchange system considerable reduces not only the maintenance time compared to previously popular air motors but also saves production time.

Wear on the vanes is a result of the working principle of the motors, the rotor turning in the off-centre cylinder. The vanes, situated in slots in the rotor, are pressed against the wall of the rotor by centrifugal force and build working chambers. The expansion of compressed supply air changes pressure energy into kinetic energy and the motor rotates. Friction is therefore created between the vanes and the rotor cylinder walls and after many hours of operation vanes become worn.

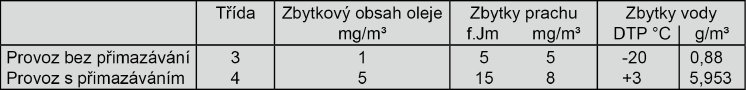

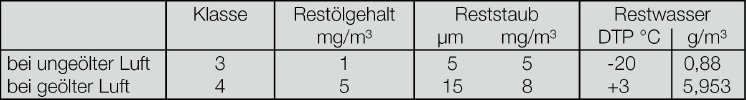

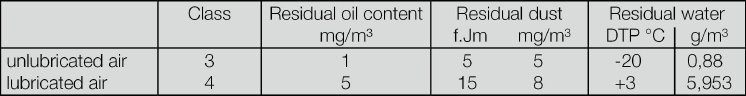

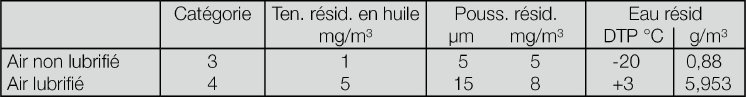

Lubricated operation improves the total lifespan of an air motor. To reach the optimum level of power and lifespan use 1-2 drops of oil per 1m³ air consumption. The supply air quality should correspond with the standard ISO 8573-1 (see image). However all BASIC LINE motors can also be operated oil-free. Unlubricated operation means shorter maintenance intervals and also a 10-20% loss of power must be calculated for the motor.

Air motors are particularly suited to use in potentially explosive environments due to their working principles: the relaxation of compressed air cools frictional heat and thereby prevents overheating and ignition of gases. In accordance with directive 94/9/EG however the suitability of an air motor for use in explosion hazardous conditions must be proven. The DEPRAG motor series BASIC LINE in accordance with ATEX II 2 GD c IIC T4 (130°C) X has a type approval certificate from an independent testing site which assures the user that the motor can be used without concern. The air motor is also suitable for "non-mining" in the category zone 1 (gas or dusty atmosphere), for materials which fall under the explosion group IIC and also up to a temperature of 130°C. In order to show the air motors' ATEX certification more clearly the typification of these motor has been altered from 63-... to 63X-....

If the supply air is suitable, this robust motor can even be operated in dusty environments without impairing its function. The internal overpressure prevents the penetration of dust and dirt.

The BASIC LINE motor series is also insensitive to heat and can under normal use be operated in temperatures from -20°C to +110°C. For the ATEX certified air motors, ATEX II 2 GD c IIC T4 (130°C) X the permissible surrounding temperature is between -20°C and max. +40°C.

Air motors are easy to regulate and it is due to their diverse features that they have such a wide ranging application. The BASIC LINE vane motor is also noted for its alternating speed as the load is altered. If the load is totally lifted then the air motor runs idly. If there is a light load, meaning a low torque on the motor spindle then the working speed of the motor runs close to idle speed, if the torque increases then the working speed decreases. The drive motor reaches maximum power at 50% of the idle speed. It is particularly energy efficient within this range.

Depending on the application the speed can be reduced by regulating the air volume by throttling either the supply air or exhaust air. Exhaust air throttling reduces the speed without significant loss of power or torque on the BASIC LINE pneumatic drive. The throttling of the supply air however is used to reduce not only the speed but also the power or the torque.

Speed can be regulated via the operating pressure as well. The technical data of the DEPRAG BASIC LINE air motors are based on an operating pressure of 6 bar. Every one of these motors can be used as required between 4 and 6.3 bar in order to adjust their power to the relevant application. The reduction of the operating pressure by 1 bar causes a reduction of the torque by 17%. If the air motor is operated at 4 bar then the torque is reduced by 33%. If the air motor rotates too quickly or is too powerful then by altering the air volume, the operating pressure or a combination of both, the speed with be altered. If the motor should be run at a lower operating pressure then the use of forced start vanes is recommended.

The air motors of the series BASIC LINE are also reversible and therefore suitable for application with either left or right rotation.

In contrast to an electric motor the gearless BASIC LINE pneumatic motor can be loaded until standstill: if overloaded the motor stops, once load is reduced it runs again straightaway and this can take place time after time with no problems. The BASIC LINE air motors are equipped with a planetary gear (with maximum torque: 80 Nm for motors in power range 200-600 W and 120 Nm for motors in the power range 900-1200 W). If an overload safe gear motor with higher torque is required then a suitable gear (planetary, spur gear, worm gear or bevel gear) can be chosen for the motor for the customer's application.

Finally the BASIC LINE motor can be used anywhere the production environment is uncritical and where a robust cast iron housing is sufficient. The customer can choose from a wide range of basic options of BASIC LINE vane motors from which, using the modular principle, individual concepts can be developed and produced as required. The series is available in the power classes 200 W, 400 W, 600 W, 900 W and 1.2 kW in a wide speed range. All BASIC LINE air motors are also equipped with a parallel key shaft.

For more demanding requirements, for example applications in cleanrooms in the food production industry or pharmaceutical industry the manufacturers offer the ADVANCED LINE series of stainless steel motors which is distinguished by its sealed, oil-free operable and rust-free air vane motors. The high quality air motors are compact and therefore the optimal solution for integration into handheld machine or system. Their power range is between 20 W to 1.2 kW, from small torques up to fast runners. The ADVANCED LINE vane motor is ATEX certified, reversible and even available with integrated holding brake.

The manufacturer also offers solutions for a more powerful range with their versatile product line POWER LINE for the higher end of 1.6 to 18 kW. Unlike electric motors, POWER LINE air motors offer high starting torque at an unequalled low power weight.

DEPRAG's range of air motors is completed with the INDIVIDUAL LINE series. The pneumatic drive of the INDIVIDUAL LINE is distinguished by their low price and individualism, enabling mass production of customised products. The standard program provides numerous versions of drive solutions which are developed and produced according to the modular principle at an attractive price to performance ratio. The specialists at DEPRAG create the perfect solution for each application case, whether designing a gear to customer requirements, varied drive spindle versions or customer specific fixtures or adaptors. They also offer air motors made from innovative materials such as ceramic.